steel tubes screw rolling machine

Short Description:

Basic Info

Model No.:YY666668

Warranty:12 Months

Delivery Time:30 Days

After Service:Engineers Available To Service Machinery Overseas

Voltage:380V/3Phase/50Hz Or At Your Request

Cutting Mode:Hydraulic

Material Of Cutting Blade:Cr12

Control System:PLC

Additional Info

Packaging:plastic film

Productivity:200 sets/year

Brand:YY

Transportation:Ocean,Land,Air

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

HS Code:84552210

Port:Tianjin,Shanghai,Qingdao

Product Description

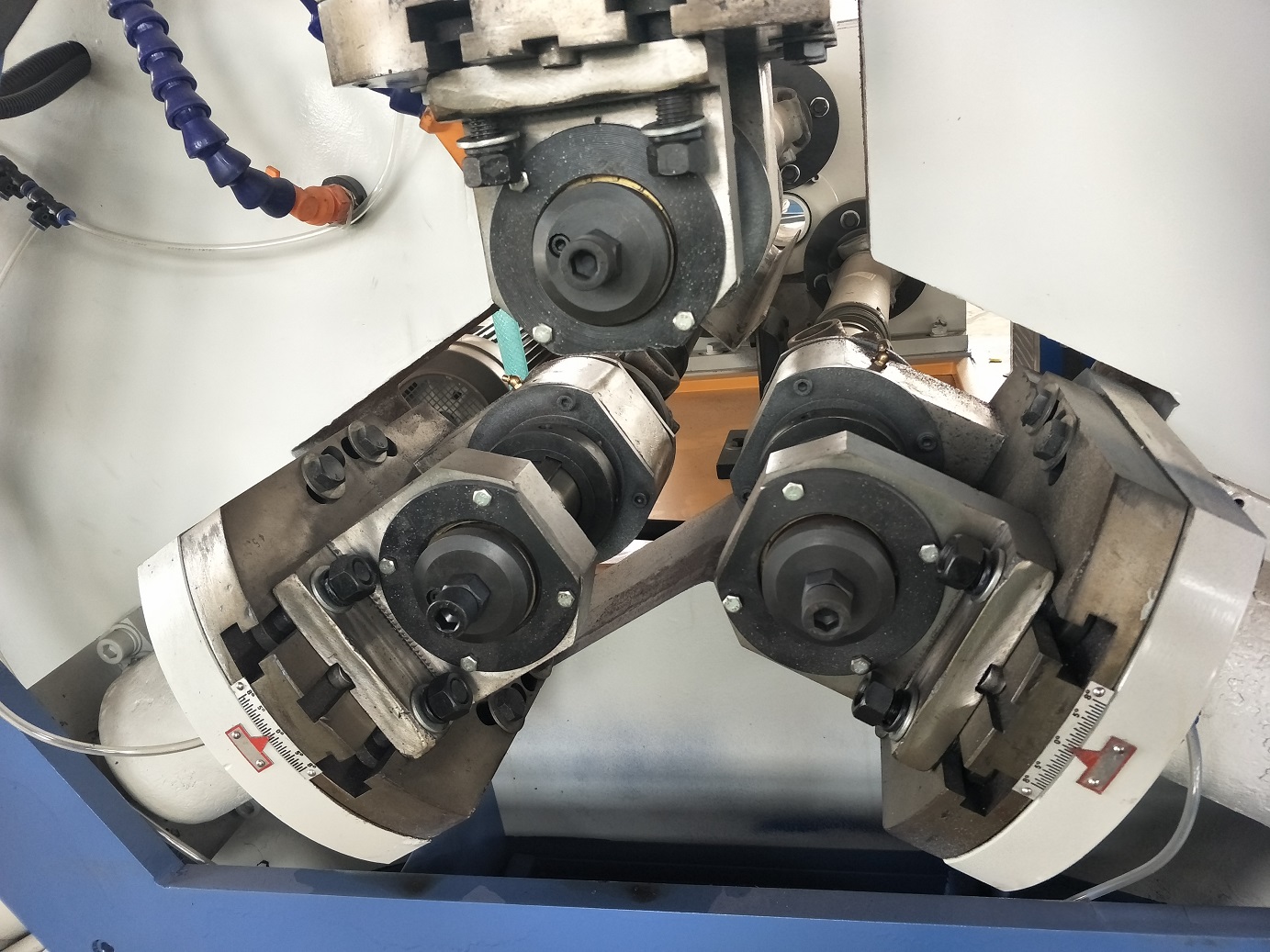

maximum pressure 250KN steel pipes Thread Rolling Machine with three shaft

Hydraulic Cutting Thread Rolling Machine Due to teeth of an internal roller brush wheel and an external roller brush wheel under the preset pressure of a spring, a steel pipe wall is bent and deformed and simultaneously is driven to rotate by the rotation of the internal roller brush wheel and the external roller brush wheel, the tube wall can generate heat due to the friction of the rotation line speed difference of the internal roller brush wheel and the external roller brush wheel, T Grid Keel Roll Forming Machine so that the strength of the material is lowered; Omega Light Keel Roll Forming Machine the material can generate rebound fatigue due to continuous rolling brush of the internal roller brush wheel and the external roller brush wheel, so that along with gradual decreasing of the rebound deform performance of the tube wall material, the teeth of the roller brush wheel are gradually pressed into the tube wall under the preset pressure, the tube wall is molded and deformed according to the teeth of the internal roller brush wheel and the external roller brush wheel, so as to form cylinder tube threads or internal and external threads of a conic tube. Roll Fomer Making Machinery,

Technical parameters:

| Pressure of Roller max. | 630KN | Rotary Speed of Main Shaft | 8,14,21,33(r/min) |

| Working Dia | 120mm | Feed Speed of Movable shaft | 5mm/s |

| OD of Roller | 260mm | Thread Length | (no limits) |

| BD of Roller | 100mm | Rolling Power | 15kw |

| Roller Width max | 200mm | Hydraulic Power | 7.5kw |

| Dip Angle of Main Shaft | ±10° | Weight | 3000kg |

| Center Distance of Main shaft | 210-380mm | Size | 2100×2270×2330mm |

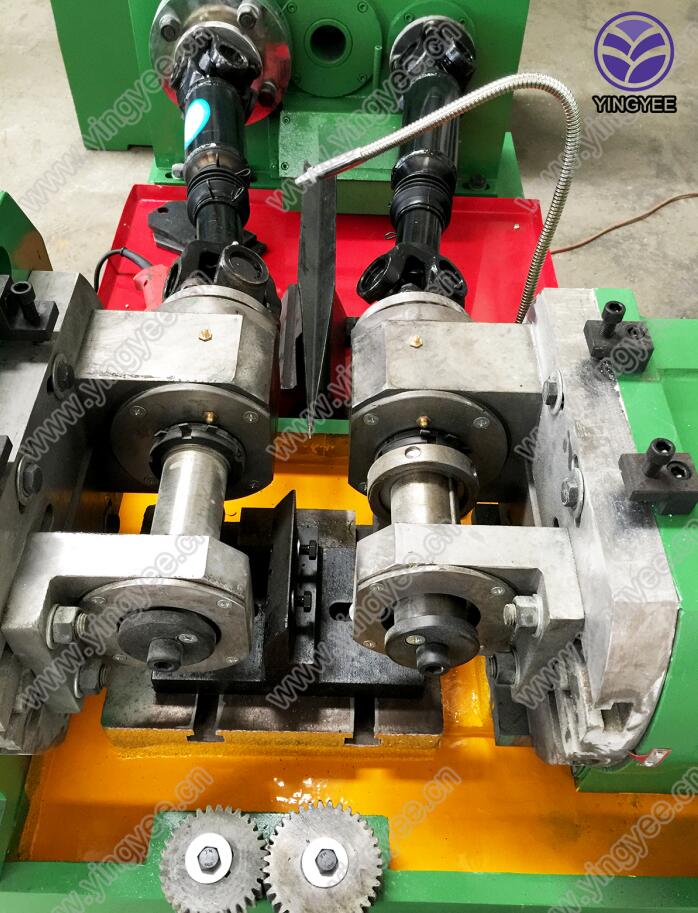

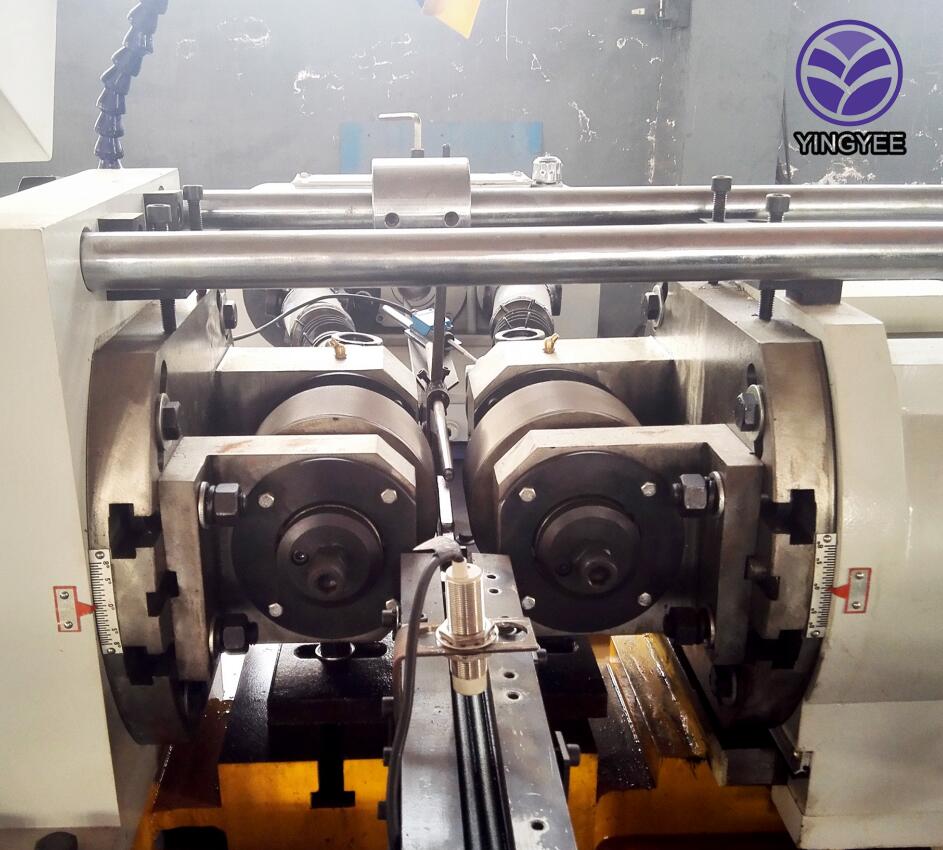

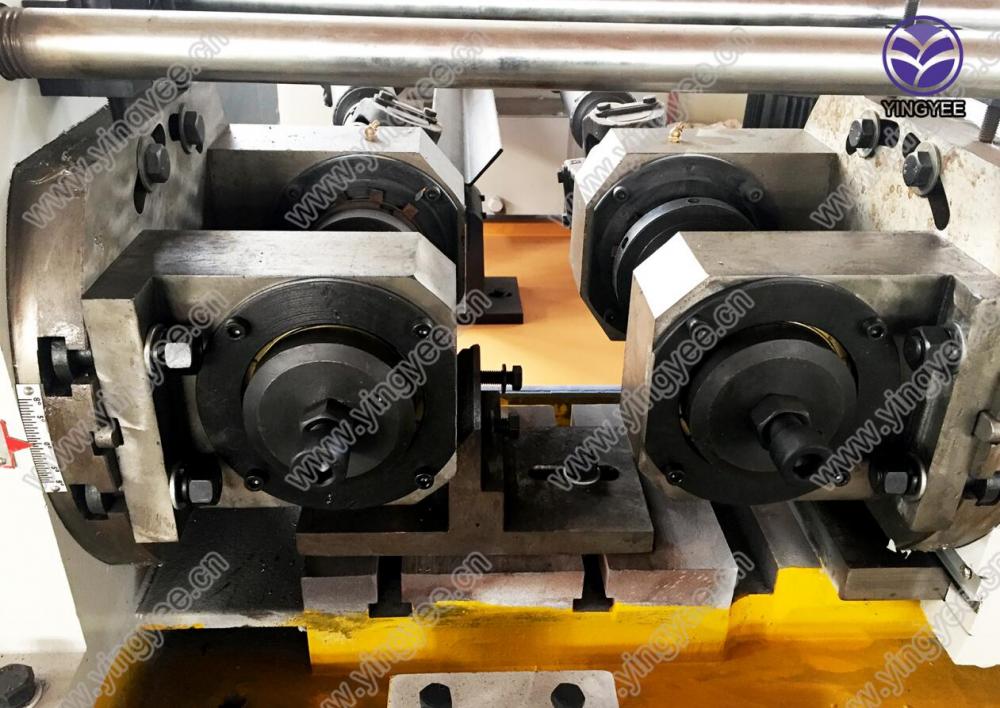

Pictures of machine:

Company information:

YINGYEE MACHINERY AND TECHNOLOGY SERVICE CO.,LTD

YINGYEE is the manufacturer specialized in various cold forming machineries and automatic production lines. We have a wonderful team with highly technology and excellent sales, which offer professional products and related service. We paid attention to quantity and after service, got great feedback and honor formal the clients. We have a great team for after service. We have sent several patch after service team to oversea to finish the products installation and adjustment. Our products were sold to more than 20 countries already. Also included US and Germany. Main product :

- Roof roll forming machine

- Roller Shutter Door Roll Forming Machine

- C and Z purlin roll forming machine

- Downpipe Roll Forming Machine

- Light keel roll forming machine

- Shearing Machine

- Hydraulic decoiler

- Bending machine

- Slitting machine

FAQ:

Training and Installation :

1. We offer installation service local in paid, reasonable charge.

2. QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service:

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period

2. Effective communication

3. Interface customized.

Looking for ideal Screw Rolling Machine Bolts Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Thread Rollings Steel Tubes are quality guaranteed. We are China Origin Factory of Steel Tubes Screw Rolling Machine. If you have any question, please feel free to contact us.

Product Categories : Thread Rolling Machine