Special Design for Composite Floor Deck Forming Machine - Galvanized Steel Downpipe Roll Former – Yingyee

Short Description:

Special Design for Composite Floor Deck Forming Machine - Galvanized Steel Downpipe Roll Former – Yingyee Detail:

Basic Info

Delivery Time:30 Days

Warranty:12 Months

Material Of Cutting Blade:Cr12

Forming Speed:25-30m/min

Material:GI, PPGI, Aluminum Coils

After Service:Engineers Available To Service Machinery Overseas

Voltage:380V/3Phase/50Hz Or At Your Request

Way Of Driven:Chain Or Gear Box

Type:Pipe Production Line

Cutting Mode:Flying Saw Cutting Or Mould Cutting

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

Product Description

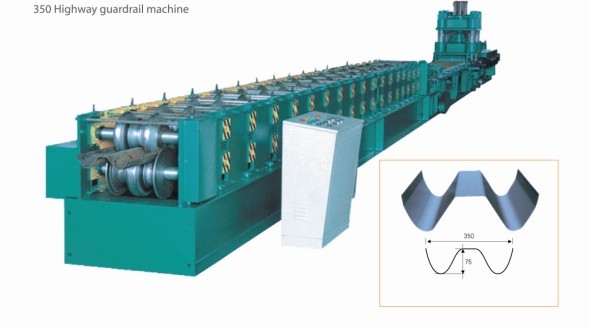

Square Downpipe Roll Forming Machine downspout gutter forming machine

To produce the best aluminum downpipe roll forming machine, YingYee Machinery is taking European quality standard, choose the best material and components, YINGYEE MACHINERY achieves that the machine capacity is double of the competitors, the machine working speed can be 25m/min, and only 1 worker to operate.

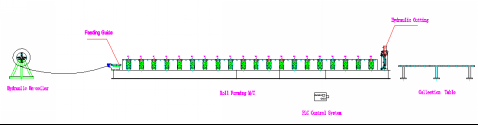

Working Flow: Decoiler – Feeding guide – Main Roll Forming Machine – PLC Contol System – Hydraulic Cutting – Output Table

Technical parameters:

| Raw material | PPGI, GI, Aluminum steel |

| Material thickness range | 0.2-0.8mm |

| Rollers | 18 rows |

| Material of forming rollers | 45# steel with chromed |

| Shaft diameter and mateiral | 76mm, material is 40Cr |

| Material of cutting blade | Cr12 mould steel with quenched treatment |

| Forming speed | 12-15m/min(excluding cutting stoping time) |

| Main motor power | 4 KW |

| Hydraulic station power | 3KW |

| Mode of cutting | Hydraulic cutting or flying saw cutting or mould cutting |

| Control system | PLC Frequency Control System with touch screen |

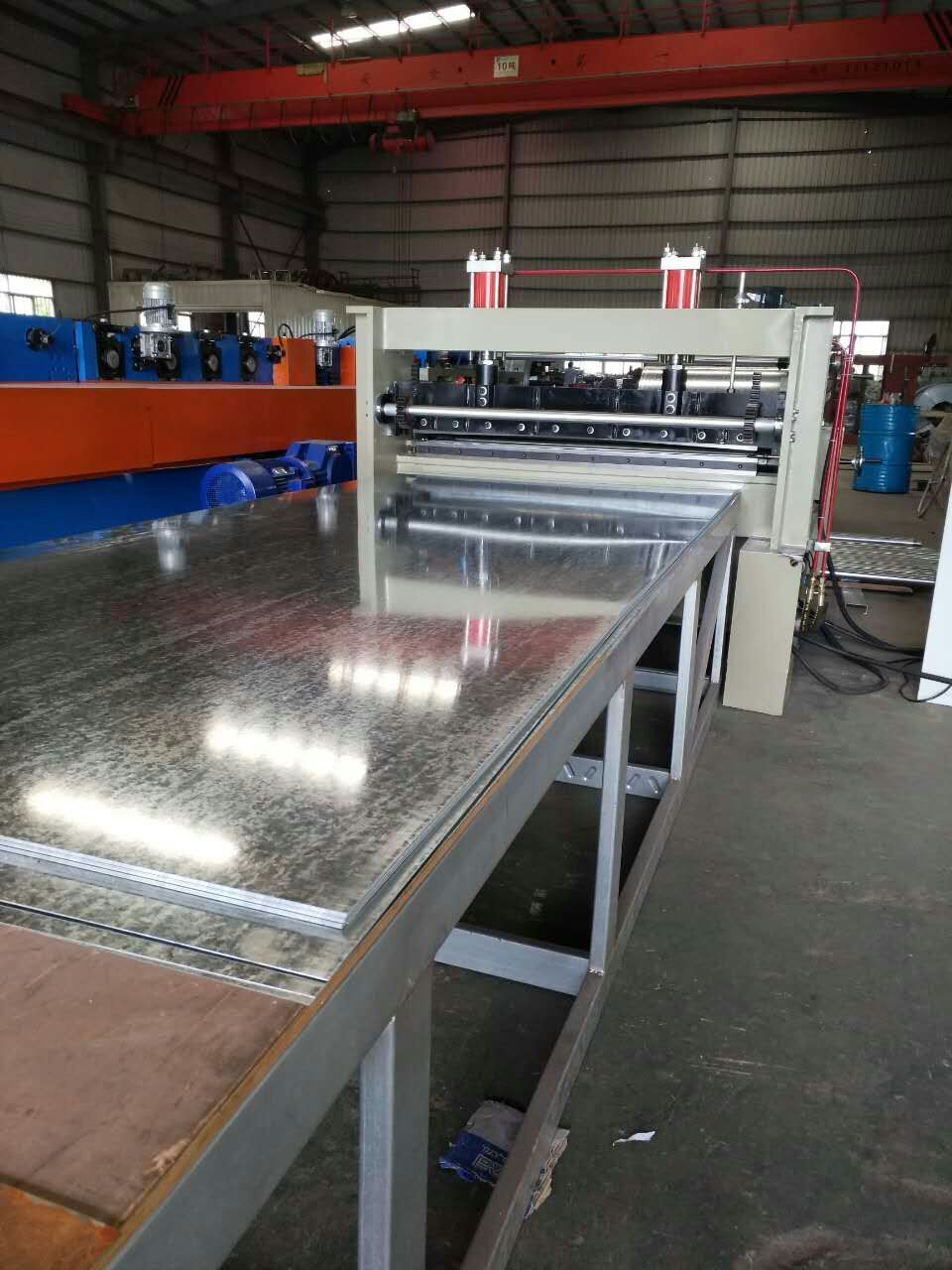

Pictures of machine:

Certification and after service:

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period

2. Effective communication

3. Interface customized.

Looking for ideal Steel Downspout Roll Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Galvanized Downspout Roll Forming Machine are quality guaranteed. We are China Origin Factory of Downspout Roll Former. If you have any question, please feel free to contact us.

Product Categories : Downpipe Roll Forming Machine > Square Downspipe Roll Forming Machine

Product detail pictures:

Related Product Guide:

With the "Client-Oriented" business philosophy, a rigorous quality control system, advanced manufacturing equipment and a strong R&D team, we always provide high quality products, excellent services and competitive prices for Special Design for Composite Floor Deck Forming Machine - Galvanized Steel Downpipe Roll Former – Yingyee, The product will supply to all over the world, such as: kazakhstan, Spain, Comoros, We have been making our products for more than 20 years . Mainly do wholesale , so we have the most competitive price , but highest quality. For the past years , we got very good feedbacks , not only because we provide good products , but also because of our good after-sale service . We are here waiting for you for your inquiry.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!