Professional Design Steel Floor Decking Forming Machine - Galvanized EPS sandwich roof panel forming machine – Yingyee

Short Description:

Professional Design Steel Floor Decking Forming Machine - Galvanized EPS sandwich roof panel forming machine – Yingyee Detail:

Basic Info

Control System:PLC

Warranty:12 Months

Delivery Time:30 Days

Type:Roof Sheet Roll Forming Machine

Cutting Mode:Hydraulic

Material:Color Coated Steel, Galvanized Steel, Aluminum St

Way Of Driven:Chain Transmission

Voltage:As Customer’s Request

After Service:Engineers Available To Service Machinery Overseas

Forming Speed:4-6m/min

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

Product Description

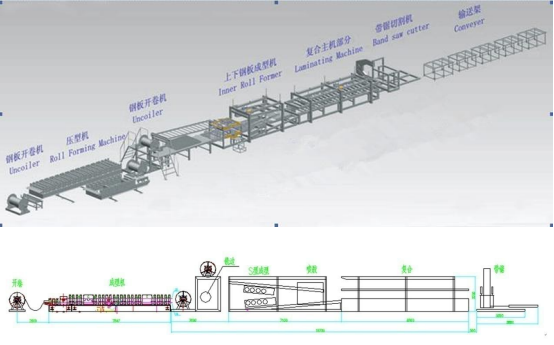

EPS sandwich roof panel production line

Our company offers High Efficiency EPS sandwich panel roll forming manufacturing machine.galvanized Eps Sandwich Panel Production Line is characterized by uninflammability, moistureproof capacity, insect-resistance, sound insulation, and light weight. Besides, it is never out of shape whether in dry or wet conditions. It has good heat preservation capacity.

Technical parameters:

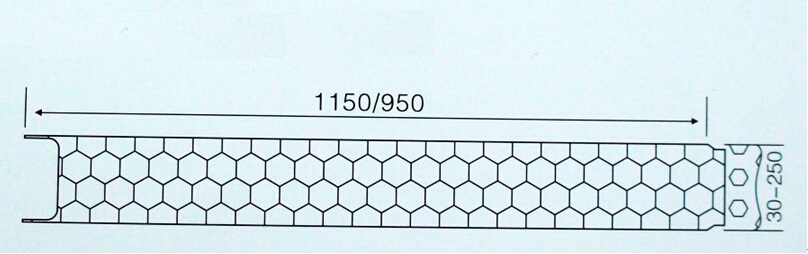

| Panel width | 950, 970,1150mm |

| Panel thickness | 50-200mm |

| Raw material | Galvanized coils, Pre-painted coils, Aluminum coils |

| Material thickness range | 0.3-0.7mm |

| width | 1000mm, 1250mm |

| yield strength | 235Mpa |

| Max coil weight | 5000kgs |

| working speed | 0-5m/min (adjustable) |

| Total length | about 35m |

| Control mode | PLC |

| Total power | about 30kw |

| Electricty condition | 380v/3phase/50hz (or depend on custmers requirement) |

Working process:

Pictures of machine:

Company information:

YINGYEE MACHINERY AND TECHNOLOGY SERVICE CO.,LTD

YINGYEE is the manufacturer specialized in various cold forming machineries and automatic production lines. We have a wonderful team with highly technology and excellent sales, which offer professional products and related service. We paid attention to quantity and after service, got great feedback and honor formal the clients. We have a great team for after service. We have sent several patch after service team to oversea to finish the products installation and adjustment. Our products were sold to more than 20 countries already. Also included US and Germany. Main product :

- Roof roll forming machine

- Roller Shutter Door Roll Forming Machine

- C and Z purlin roll forming machine

- Downpipe Roll Forming Machine

- Light Keel Roll Forming Machine

- Shearing Machine

- Hydraulic decoiler

- Bending machine

- Slitting machine

FAQ:

Training and Installation :

1. We offer installation service local in paid, reasonable charge.

2. QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service:

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period.

2. Effective communication

3. Interface customized.

Looking for ideal Galvanized EPS Sandwich Panel Production Line Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Sandwich Production Line are quality guaranteed. We are China Origin Factory of Sandwich Roof Panel Roll Forming Machine. If you have any question, please feel free to contact us.

Product Categories : Sandwich Panel Production Line

Product detail pictures:

Related Product Guide:

Our growth depends to the superior products ,great talents and repeatedly strengthened technology forces for Professional Design Steel Floor Decking Forming Machine - Galvanized EPS sandwich roof panel forming machine – Yingyee, The product will supply to all over the world, such as: Plymouth, Austria, Libya, We accomplish this by exporting our wigs directly from our own factory to you. The goal of our company is to get customers who enjoy coming back to their business. We sincerely hope to cooperate with you in the near future. If there's any opportunity, welcome to visit our factory!!!

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.