-

light steel stud track making machine

Basic Info Model No.:YY–STM—003 Control System:PLC Delivery Time:30 Days Warranty:12 Months Material Of Cutting Blade:Cr12 Type:Steel Frame & Purlin Machine After Service:Engineers Available To Service Machinery Overseas Voltage:380V/3Phase/50Hz Or At Your Request Cutting Mode:Servo Tracking Cutting Way Of Driven:Gear Forming Speed:0-45m/min(include Punching) Additional Info Packaging:NUDE Productivity:200 sets/year Brand:YY Transportation:Ocean Place of Origin:Hebei Sup... -

C/U profile stud and track forming machine

Basic Info Model No.:YY–STM—008 Control System:PLC Delivery Time:30 Days Warranty:12 Months Material Of Cutting Blade:Cr12 Type:Steel Frame & Purlin Machine After Service:Engineers Available To Service Machinery Overseas Voltage:380V/3Phase/50Hz Or At Your Request Cutting Mode:Servo Tracking Cutting Way Of Driven:Gear Forming Speed:0-45m/min(include Punching) Additional Info Packaging:NUDE Productivity:200 sets/year Brand:YY Transportation:Ocean Place of Origin:Hebei Sup... -

high speed stud and track make machine

Basic Info Model No.:YY- -stm—001 Control System:PLC Delivery Time:30 Days Warranty:12 Months Material Of Cutting Blade:Cr12 Cutting Mode:Servo Tracking Cutting Type:Steel Frame & Purlin Machine After Service:Engineers Available To Service Machinery Overseas Voltage:380V/3Phase/50Hz Or At Your Request Forming Speed:0-45m/min(include Punching) Way Of Driven:Gear Additional Info Packaging:NUDE Productivity:200 sets/year Brand:YY Transportation:Ocean Place of Origin:Hebei Supply ... -

galvanized aluminum stud and track making machine

Basic Info Control System:PLC Delivery Time:30 Days Warranty:12 Months Material Of Cutting Blade:Cr12 Type:Steel Frame & Purlin Machine After Service:Engineers Available To Service Machinery Overseas Voltage:380V/3Phase/50Hz Or At Your Request Way Of Driven:Chain Or Gear Box Forming Speed:30-40m/min(excluding Punching) Cutting Mode:Servo Tracking Cutting Additional Info Packaging:NUDE Productivity:200 sets/year Brand:YY Transportation:Ocean Place of Origin:Hebei Supply Ability:200 s... -

Stud And Track Keel Forming Machine

Basic Info Control System:PLC Delivery Time:30 Days Warranty:12 Months Material Of Cutting Blade:Cr12 Type:Steel Frame & Purlin Machine After Service:Engineers Available To Service Machinery Overseas Voltage:380V/3Phase/50Hz Or At Your Request Way Of Driven:Chain Or Gear Box Forming Speed:30-40m/min(excluding Punching) Cutting Mode:Servo Tracking Cutting Additional Info Packaging:NUDE Productivity:200 sets/year Brand:YY Transportation:Ocean Place of Origin:Hebei Supply Ability:200 s... -

sale stud and track c channel drywall main furring wall angle making machine

Basic Info Control System:PLC Delivery Time:30 Days Warranty:12 Months Material Of Cutting Blade:Cr12 Type:Steel Frame & Purlin Machine After Service:Engineers Available To Service Machinery Overseas Voltage:380V/3Phase/50Hz Or At Your Request Way Of Driven:Chain Or Gear Box Forming Speed:30-40m/min(excluding Punching) Cutting Mode:Servo Tracking Cutting Additional Info Packaging:NUDE Productivity:200 sets/year Brand:YY Transportation:Ocean Place of Origin:Hebei Supply Ability:200 s... -

Ceiling Tee bar roll forming machine

Basic Info Control System:PLC Delivery Time:30 Days Warranty:12 Months Material Of Cutting Blade:Cr12 Cutting Mode:Servo Tracking Cutting Type:Steel Frame & Purlin Machine After Service:Engineers Available To Service Machinery Overseas Voltage:380V/3Phase/50Hz Or At Your Request Way Of Driven:Chain Or Gear Box Forming Speed:30-40m/min(excluding Punching) Additional Info Packaging:NUDE Productivity:200 sets/year Brand:YY Transportation:Ocean Place of Origin:Hebei Supply Ability:200 s... -

Cross Tee Grid Making Machine Keel

Basic Info Control System:PLC Delivery Time:30 Days Warranty:12 Months Material Of Cutting Blade:Cr12 Cutting Mode:Servo Tracking Cutting Type:Steel Frame & Purlin Machine After Service:Engineers Available To Service Machinery Overseas Voltage:380V/3Phase/50Hz Or At Your Request Way Of Driven:Chain Or Gear Box Forming Speed:30-40m/min(excluding Punching) Additional Info Packaging:NUDE Productivity:200 sets/year Brand:YY Transportation:Ocean Place of Origin:Hebei Supply Ability:200 s... -

Slitting coils into strips

Basic Info Feeding Material:0.12-1.0mm Speed:Line Speed 55-60m/min Cutting Speed:(for 2000mm) 25-30pieces/min Leveling Rollers Material:40Cr With Chromed 0.1mm Uncolier:Capacity 15T Hydraulic With Trolley Additional Info Packaging:Nuded Productivity:20 sets Brand:YY Transportation:Ocean Place of Origin:Hebei Supply Ability:20 sets Certificate:CE/ISO9001 HS Code:84552210 Port:Tianjin Xingang Product Description Automatic Slitting Line for Steel coils Looking for ideal Slitt... -

Electrical Junction Box forming machine

Decoiler

Coils width: ≤462mm;

Material thickness 0.6mm;

Material roll inner diameter: ≥φ450mm;

Max.OD Coil: φ1200mm; Weight: ≤3T; Spindle center height: 650mm

Land size (length x width) 1200x1000mm

Traction and Leveling machine

Number of work rolls: 11 rolls leveling

It consists of a pinch roller and a leveling roller. The pinch roller can be adjusted individually. The feeding end of the

leveling machine is equipped with a pair of guiding flat rollers and two pairs of guiding vertical rollers. The guiding vertical

rollers can move in the center and move at the same time.

Diameter of leveling roller: 60MM

Distance between leveling rollers: 65MM

NCF-500 Servo Feeder

Function: Measure the length of the workpiece and work requirements for traction, feeding and stamping.

Structural features: Two pairs of traction rollers, traction roller reduction adjustment device, frame, servo motor, etc.;

Servo motor control: Fixed-length feeding;

LCD touch screen: easy to change and set various technical parameters.

Parameter:

(1) The maximum passing width of the sheet is 462mm

(2) Feeding method: Servo feeding

(3) Feeding times according to punching times

Punching system

1. Composed of 4 hydraulic punching machine

2. Component:Base, hydraulic pressure device, hydraulic system, etc.;

3. Parameter: (1) Rated pressure 16Mpa-25 Mpa

(2) Power 7.5KW

4. Function: Complete the logo and hook/cut angle of 2F board.

Complete the logo and hook/cut blanking of the 1F board to provide a sheet for the single hand plug forming.

Roll forming machine

Machine 1 for Fundo F2: Torii through shaft

structure + cantilevered host structure; Complete continuous feeding molding.

Machine 2 for Fundo F1: Torii through shaft structure + cantilevered host structure; Complete single-sheet hand plug feeding

forming.

Structure: Quick-change type adjustment mechanism. The bed adopts welded structure and stress relief treatment; the gear adopts 45

steel hard tooth surface;

High strength, high hardness, high precision, high service life.

Parameters:

(1) Raw material thickness 0.6mm (when σs≤260Mpa)

(2) Raw material width ≤462mm (adjustable)

(3) Forming passes: Forming machine ①: 17 passes; Forming machine ②: 12 passes

(4) Motor power 5.5kw, frequency conversion motor

(5) Transmission mode Gear transmission

(6) Rolling mill speed 0-12m/min

(7) Roll material Cr12 quenched HRC56°-60°

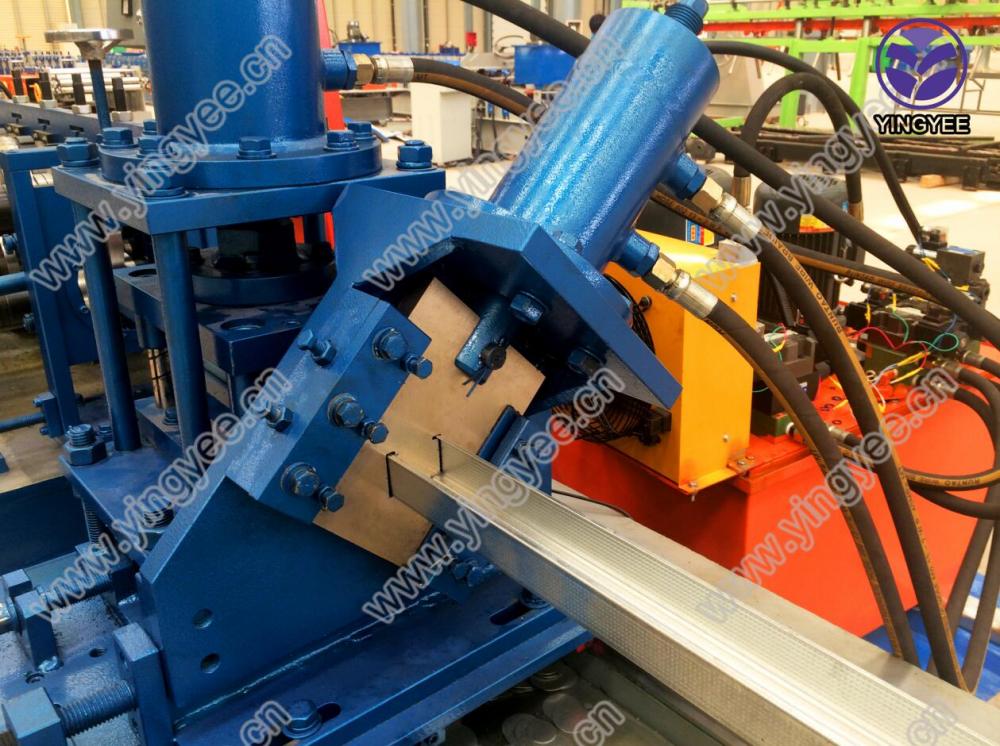

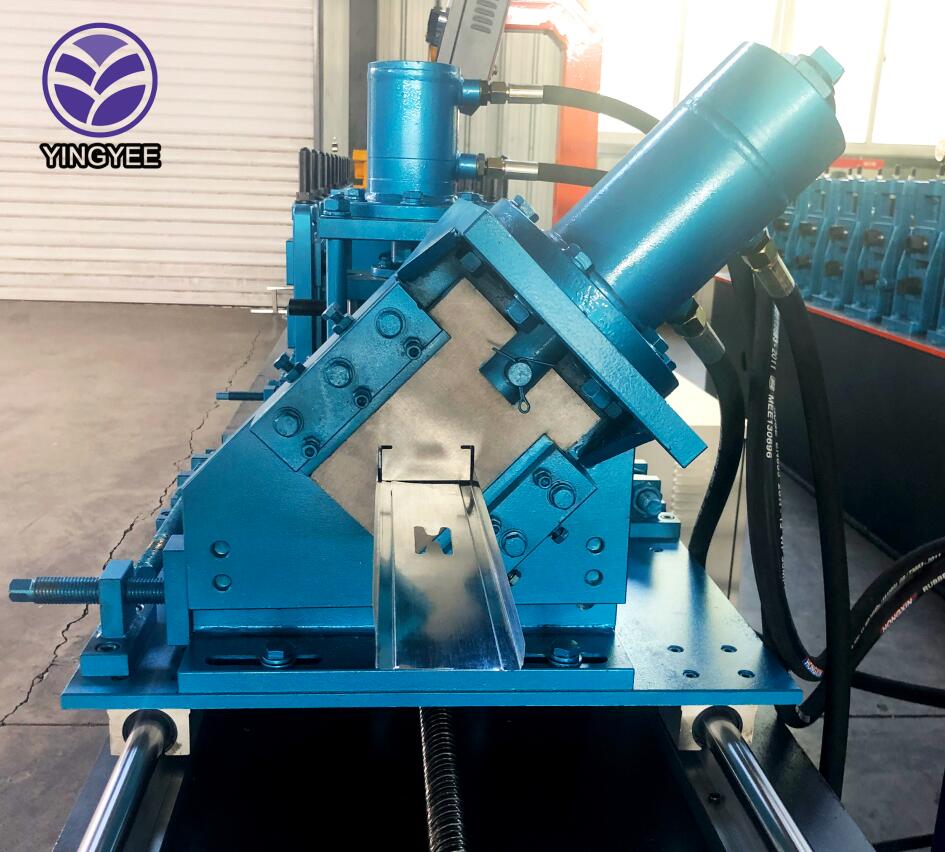

Automatic Hydraulic track cutting machine

Function: Automatically cut and bend the cold-formed profile on-line according to the size requirements.

Stucture:

Cutting head: Cylinder, top plate, column, base plate.

Machine body: Plates, wheels, axles, frame bodies, buffers, base beams, etc.

Parameters:

(1) Maximum cut section (length×width) 433×16mm

(2) Land size (length×width): 1000mm×800mm

(3) Hydraulic power: 4kw

Receiving table

Structure: roller type, no power; composed of bed, support, roller shaft,

Electrical control system

The whole line adopts PLC control, LCD touch

screen, man-machine interface.

Function:

(1) Digital setting of part length.

(2) The length of the parts can be adjusted.

(3) Real-time monitoring of equipment operating status and fault indication.

There are two modes of operation: manual/automatic

In the manual state, it can be operated as a stand-alone machine, which is convenient for maintenance; in the automatic state, the

whole line of production operation is carried out, and the sequence starts

Emergency stop buttons on the whole line, which are easy to handle emergency accidents and ensure the safety of equipment and

operators -

Heavy duty storage racks roll forming machine

Storage Rack/Beam/Upright Roll Forming Making Machinery -

High speed without noises steel angle stud and track sale stud and track c channel drywall main furring wall angle roll forming machine

Part Name Technical Specification Mamual decoiler capacity: 3 Tons Double Head Decoiler (No power) Feeding guide system Input width adjustable Mainly forming system Main power: 7.5kwMachine Body: Torrist stand with iron castingFrame:All steel plate for machine bodyForming speed: 75m/min for producing both Stud and TrackShaft material and diameters: #45 steel and 60mmRoller material:: Cr12 with well heat treatment ,58-62Forming Steps: 10 -14 steps for forming Driven: Gear Box Elec...