-

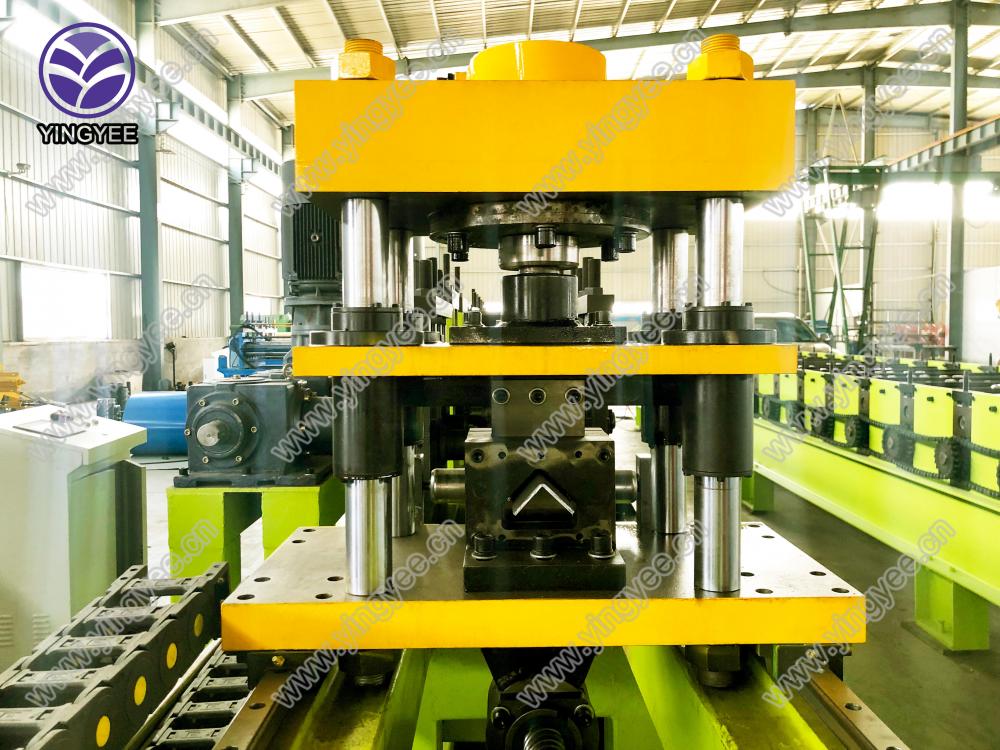

Galvanized Steel Angle Roll Forming machine

Basic Info Model No.:YY–SAM—008 Condition:New Customized:Customized Automatic Grade:Automatic Structure:Other Transmission Method:Machinery Control System:PLC Material Of Roller:Cr12mov Main Power:15kw Speed:25m/min Transmission:Gear Box Hydraulic Power:11KW Cut Type:Servo Hydraulic Cutting Thickness:1.0-2.5 Mm Additional Info Packaging:Naked Productivity:200 sets/year Brand:YINGYEE Transportation:Ocean Place of Origin:China Supply Ability:200 sets/year Certificate:ISO9001 ... -

Automatic Hydraulic guillotine shearing machine

Basic Info Warranty:12 Months Delivery Time:30 Days Control System:PLC Material Of Cutting Blade:Cr12 After Service:Engineers Available To Service Machinery Overseas Voltage:380V/3Phase/50Hz Or At Your Request Cutting Mode:Hydraulic Cutting Or Electric Cutting Forming Speed:8-10m/min Additional Info Packaging:NUDE Productivity:200 sets/year Brand:YY Transportation:Ocean Place of Origin:Hebei Supply Ability:200 sets/year Certificate:CE/ISO9001 Product Description Hydraulic Shearin... -

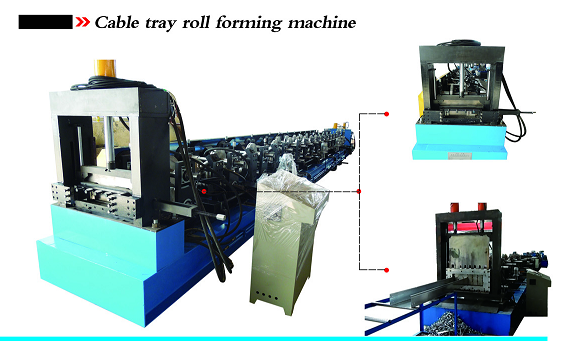

Cable Tray Manufacturing Machine

Basic Info Warranty:12 Months Delivery Time:30 Days After Service:Engineers Available To Service Machinery Overseas Forming Speed:25-30m/min(excluding Punching) Cutting Mode:Hydraulic Material Of Cutting Blade:Cr12 Type:Steel Frame & Purlin Machine Control System:PLC Voltage:380V/3Phase/50Hz Or At Your Request Way Of Driven:Chain Or Gear Box Additional Info Packaging:NUDE Productivity:200 sets/year Brand:YY Transportation:Ocean Place of Origin:Hebei Supply Ability:200 sets/year C... -

Automatic Adjust C Z-Purlin Sizes Roll Forming Machine

The structural C and Z purlins are for industrial buildings, garages, verandahs, and carports; anywhere that strong reliable steel framing is required. Manufactured from quality galvanised steel, this is a fully integrated system allowing for flexible design options.

Our machine is the best choice in roll forming machines for the U-C-Channel, Lipped Channel, and Z-shaped profiles.

The machine adjusts the size of c/u/z by PLC automatic type, for c u to z change can be finished in two minutes. -

cantilever type cable tray roll forming machine

Basic Info Warranty:12 Months Delivery Time:30 Days After Service:Engineers Available To Service Machinery Overseas Forming Speed:25-30m/min(excluding Punching) Cutting Mode:Hydraulic Material Of Cutting Blade:Cr12 Type:Steel Frame & Purlin Machine Control System:PLC Voltage:380V/3Phase/50Hz Or At Your Request Way Of Driven:Chain Or Gear Box Additional Info Packaging:NUDE Productivity:200 sets/year Brand:YY Transportation:Ocean Place of Origin:Hebei Supply Ability:200 sets/year C... -

High speed Roller door panels Forming Machine

Basic Info Type:Steel Frame & Purlin Machine Control System:PLC Delivery Time:30 Days Warranty:12 Months Material Of Cutting Blade:Cr12 Cutting Mode:Hydraulic After Service:Engineers Available To Service Machinery Overseas Forming Speed:25-30m/min(excluding Punching) Voltage:380V/3Phase/50Hz Or At Your Request Way Of Driven:Chain Or Gear Box Additional Info Packaging:NUDE Productivity:200 sets/year Brand:YY Transportation:Ocean Place of Origin:Hebei Supply Ability:200 sets/year C... -

Angle Sale Stud and Track C Channel Drywall Main Furring Wall Angle Roll Forming Machine

Angle Keel Roll Forming Machine by bello lin is a type of Caigang pressure equipment, it uses galvanized or aluminum coils as raw materials, formed through continuous cold rolling. In accordance with the requirements of customers design, and manufacture different specifications of cold bending and paint equipment. And it is an indispensable part of, angle steel and L-shaped steel keel in the interior of the house. -

Double Out Stud and Track/C Channel/Drywall/Gypsum Stud/Wall Angle Roll Forming Machine

Double-out light keel machines have two different model designs that can be made in one machine. That kind of design would save the cost of the machine and the space of the warehouse. It has the advantage of a lightweight, neat appearance. Such as metal studs and track roll-forming machines. -

Aluminium Enclosure Box Forming Machine

Decoiler

Coils width: ≤462mm;

Material thickness 0.6mm;

Material roll inner diameter: ≥φ450mm;

Max.OD Coil: φ1200mm; Weight: ≤3T; Spindle center height: 650mm

Land size (length x width) 1200x1000mm

Traction and Leveling machine

Number of work rolls: 11 rolls leveling

It consists of a pinch roller and a leveling roller. The pinch roller can be adjusted individually. The feeding end of the

leveling machine is equipped with a pair of guiding flat rollers and two pairs of guiding vertical rollers. The guiding vertical

rollers can move in the center and move at the same time.

Diameter of leveling roller: 60MM

Distance between leveling rollers: 65MM

NCF-500 Servo Feeder

Function: Measure the length of the workpiece and work requirements for traction, feeding and stamping.

Structural features: Two pairs of traction rollers, traction roller reduction adjustment device, frame, servo motor, etc.;

Servo motor control: Fixed-length feeding;

LCD touch screen: easy to change and set various technical parameters.

Parameter:

(1) The maximum passing width of the sheet is 462mm

(2) Feeding method: Servo feeding

(3) Feeding times according to punching times

Punching system

1. Composed of 4 hydraulic punching machine

2. Component:Base, hydraulic pressure device, hydraulic system, etc.;

3. Parameter: (1) Rated pressure 16Mpa-25 Mpa

(2) Power 7.5KW

4. Function: Complete the logo and hook/cut angle of 2F board.

Complete the logo and hook/cut blanking of the 1F board to provide a sheet for the single hand plug forming.

Roll forming machine

Machine 1 for Fundo F2: Torii through shaft

structure + cantilevered host structure; Complete continuous feeding molding.

Machine 2 for Fundo F1: Torii through shaft structure + cantilevered host structure; Complete single-sheet hand plug feeding

forming.

Structure: Quick-change type adjustment mechanism. The bed adopts welded structure and stress relief treatment; the gear adopts 45

steel hard tooth surface;

High strength, high hardness, high precision, high service life.

Parameters:

(1) Raw material thickness 0.6mm (when σs≤260Mpa)

(2) Raw material width ≤462mm (adjustable)

(3) Forming passes: Forming machine ①: 17 passes; Forming machine ②: 12 passes

(4) Motor power 5.5kw, frequency conversion motor

(5) Transmission mode Gear transmission

(6) Rolling mill speed 0-12m/min

(7) Roll material Cr12 quenched HRC56°-60°

Automatic Hydraulic track cutting machine

Function: Automatically cut and bend the cold-formed profile on-line according to the size requirements.

Stucture:

Cutting head: Cylinder, top plate, column, base plate.

Machine body: Plates, wheels, axles, frame bodies, buffers, base beams, etc.

Parameters:

(1) Maximum cut section (length×width) 433×16mm

(2) Land size (length×width): 1000mm×800mm

(3) Hydraulic power: 4kw

Receiving table

Structure: roller type, no power; composed of bed, support, roller shaft,

Electrical control system

The whole line adopts PLC control, LCD touch

screen, man-machine interface.

Function:

(1) Digital setting of part length.

(2) The length of the parts can be adjusted.

(3) Real-time monitoring of equipment operating status and fault indication.

There are two modes of operation: manual/automatic

In the manual state, it can be operated as a stand-alone machine, which is convenient for maintenance; in the automatic state, the

whole line of production operation is carried out, and the sequence starts

Emergency stop buttons on the whole line, which are easy to handle emergency accidents and ensure the safety of equipment and

operators -

Electronic Instrument Box Equipment

Parameters:

(1) Maximum cut section (length×width): 433×16mm

(2) Land size (length×width): 1000mm×800mm

(3) Hydraulic power: 4kw

Receiving table:

Structure: roller type, no power; composed of bed, support, roller shaft, electrical control system

The whole line adopts PLC control, LCD touch screen, and man-machine interface.

Function:

(1) Digital setting of part length.

(2) The length of the parts can be adjusted.

(3) Real-time monitoring of equipment operating status and fault indication.

There are two modes of operation: manual/automatic

In the manual state, it can be operated as a stand-alone machine, which is convenient for maintenance; in the automatic state, the whole line of production operation is carried out, and the sequence starts.

Emergency stop buttons on the whole line, make it easy to handle emergency accidents and ensure the safety of equipment and operators. -

600-1500 Prepainted Galvanized Steel Coils

600-1500 Prepainted Galvanized steel coils are pre-painted galvanized steel, also known as pre-coated steel, color-coated steel, etc.

Using Hot Galvanized Steel Coil as the substrate, PPGI is made by first going through surface pretreatment, then the coating of one or more layers of liquid coating by roll coating, and finally baking and cooling. The coatings used include polyester, silicon modified polyester, high-durability, corrosion-resistance, and formability.

We are a PPGI & PPGL Supplier, in China. Our PPGI (Prepainted Galvanized Steel) & PPGL (Prepainted Galvalume Steel) are available in a variety of specifications.

We could also provide the product life length lasts for decades as customers require 600-1500 Prepainted Galvanized steel coils. -

PPGI Prepainted Galvanized Coils

PPGI is pre-painted galvanized steel, also known as pre-coated steel, color-coated steel, etc.

Using Hot Galvanized Steel Coil as the substrate, PPGI is made by first going through surface pretreatment, then the coating of one or more layers of liquid coating by roll coating, and finally baking and cooling. The coatings used include polyester, silicon modified polyester, high-durability, corrosion-resistance, and formability.

We are a PPGI & PPGL Supplier, in China. Our PPGI (Prepainted Galvanized Steel) & PPGL (Prepainted Galvalume Steel) are available in a variety of specifications.

We could also provide the product life length lasts for decades as customers require.