OEM/ODM Factory Press Brake Bending Machine - Metal storage rack /upright pillar roll forming machine – Yingyee

Short Description:

OEM/ODM Factory Press Brake Bending Machine - Metal storage rack /upright pillar roll forming machine – Yingyee Detail:

Basic Info

Type:Steel Frame & Purlin Machine

Warranty:12 Months

Delivery Time:30 Days

After Service:Engineers Available To Service Machinery Overseas

Forming Speed:25-30m/min(excluding Punching And Cutting Time)

Cutting Mode:Hydraulic

Material Of Cutting Blade:Cr12

Control System:PLC

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

Product Description

Metal storage rack /column/ upright pillar working system

The upright shelf system is mainly composed by the column, steel plate composition. Column with roll forming process, with the oblique rod, horizontal rod connected to form a column. According to the needs of the side beam with a layer of laminates or beams used, the board can be adjusted for every 50 mm pitch up and down any height, the shelf for the modular structure, high stability, easy installation and disassembly. Unit shelf each load between 200kg-800kg, the total load is generally not more than 5000kg. Unit shelf span is usually not more than 2.6m, the depth of not more than 1.2m, the height is generally within 5m. Applicable to carrying small and medium goods.Widely used in shopping malls, supermarkets, corporate warehouses and institutions and other industries.

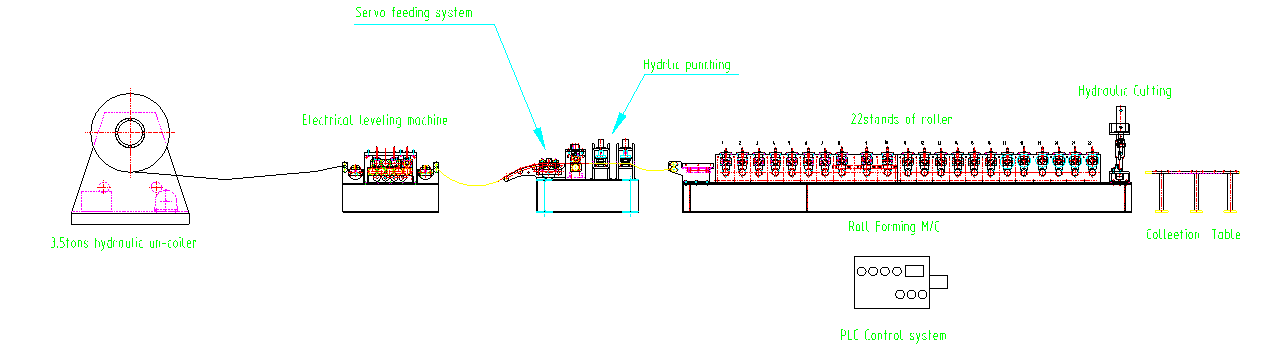

Working Flow: Decoiler – Feeding Guide – Servo feeding system – Hydraulic punching – Main Roll Forming Machine – PLC Contol System – Hydraulic Cutting – Output Table

Technical parameters:

| Matching material | Color steel plate, Galvanized, PPGI, Aluminum |

| Material thickness range | 1.5-3mm |

| Main motor power | 15KW |

| Hydraulic power | 11KW |

| Forming speed | 6-8m/min(include punching) |

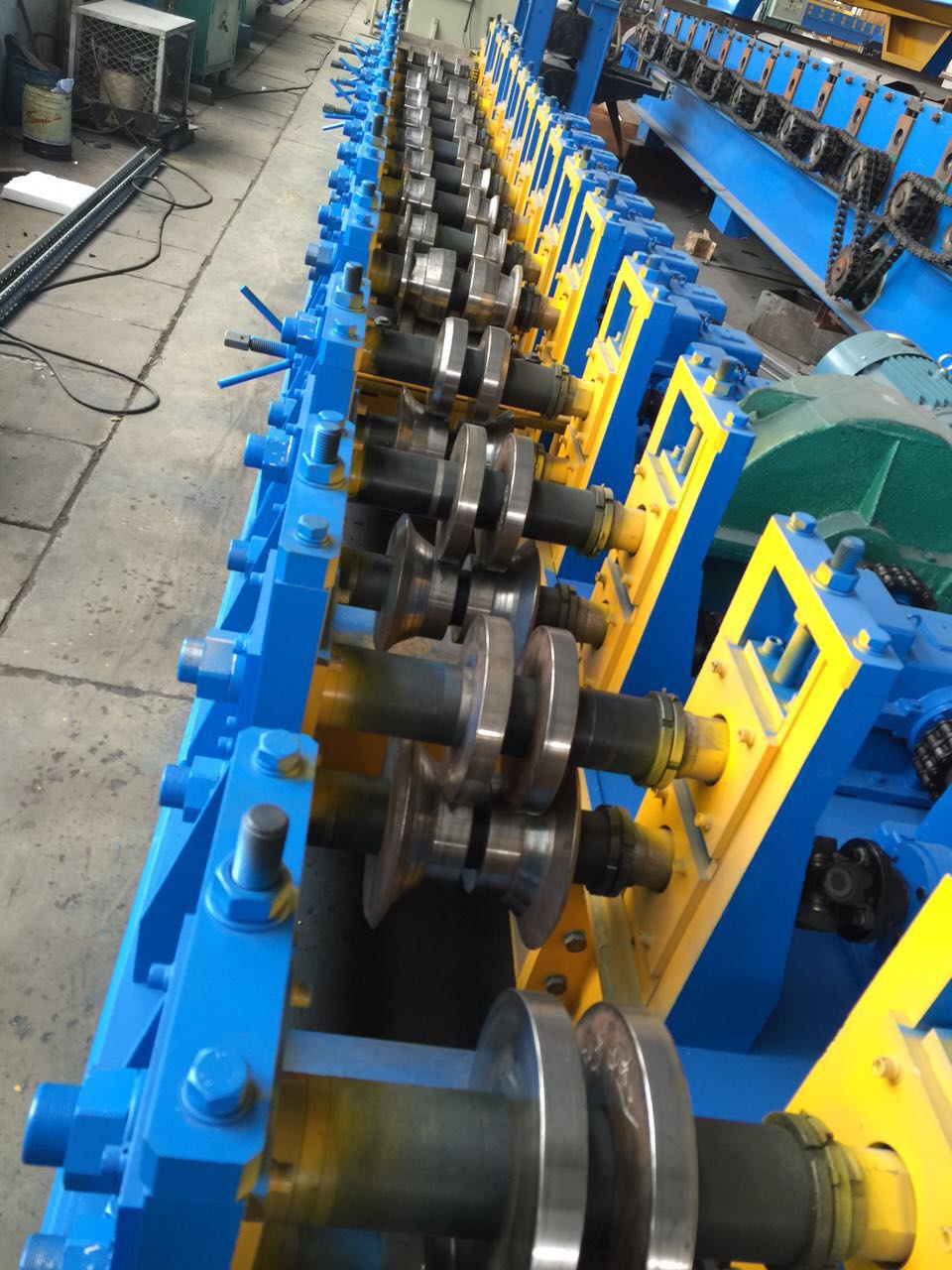

| Rollers | 18-24 rows |

| Material of rollers | 45# steel with chromed |

| Shaft material and diameter | 80mm, material is 40Cr |

| Way of driven | Chain transmission or Gear box |

| Controlling system | Siemens PLC |

| Voltage | 380V/3Phase/50Hz |

| Material of blade | Cr12 mould steel with quenched treatment 58-62℃ |

| Total weight | about 15 tons |

| Size of the machine | L*W*H 12m*2.0m*1.6m |

Pictures of machine:

FAQ:

Training and Installation :

1. We offer installation service local in paid, reasonable charge.

2. QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service:

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period

2. Effective communication

3. Interface customized.

Looking for ideal C Type Rolling Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Storage Rack Rolling Machine are quality guaranteed. We are China Origin Factory of Storage Rack Metal Sheet Machine. If you have any question, please feel free to contact us.

Product Categories : Storage Rack Roll Forming Machine > Storage Upright Roll Forming Machine

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our development strategy for OEM/ODM Factory Press Brake Bending Machine - Metal storage rack /upright pillar roll forming machine – Yingyee, The product will supply to all over the world, such as: moldova, Swedish, Oman, We hope we can establish long-term cooperation with all of the customers. And hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!