OEM/ODM Factory Mesh Welding Machine - Double out light keel roll forming machine – Yingyee

Short Description:

OEM/ODM Factory Mesh Welding Machine - Double out light keel roll forming machine – Yingyee Detail:

Basic Info

Control System:PLC

Delivery Time:30 Days

Warranty:12 Months

Material Of Cutting Blade:Cr12

Type:Steel Frame & Purlin Machine

After Service:Engineers Available To Service Machinery Overseas

Voltage:380V/3Phase/50Hz Or At Your Request

Way Of Driven:Chain Or Gear Box

Forming Speed:30-40m/min(excluding Punching)

Cutting Mode:Servo Tracking Cutting

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

Product Description

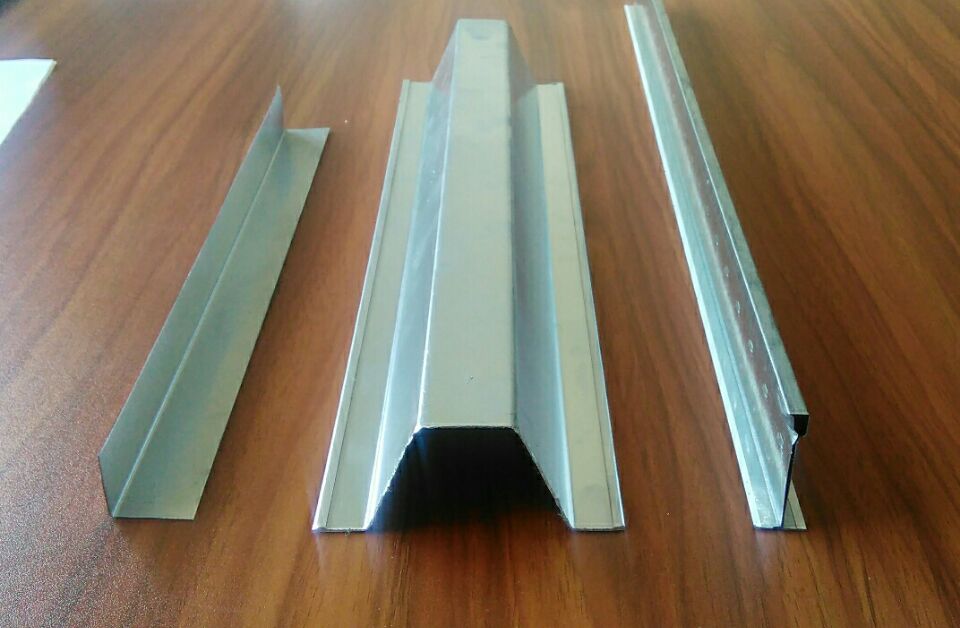

Double out Light Keel Roll Forming Machine

Double out light keel machine have two different model design can be made in one machine. That kind of design would save the cost of machine, and the space of warehouse. It has the advantage of light weight, neat appearance.Such as metal stud and track roll forming machine.

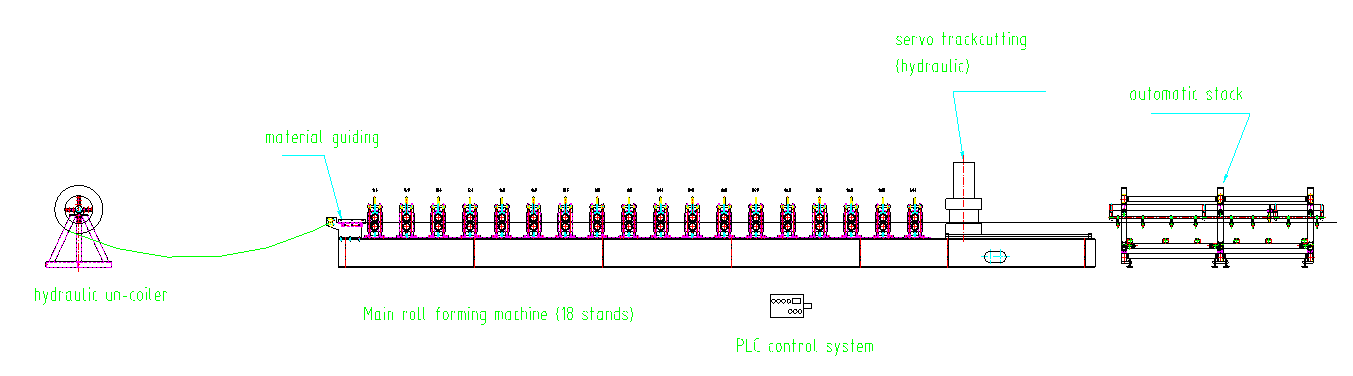

Working process:

Decoiler – Feeding guide – Straighteing – Main roll forming machine – PLC control system – Servo tracking cutting – Receiving table

Technical parameters:

| Raw material | PPGI, GI, Aluminum coils |

| Material thickness range | 0.3-1mm |

| Forming speed | 30-40m/min(without punching) |

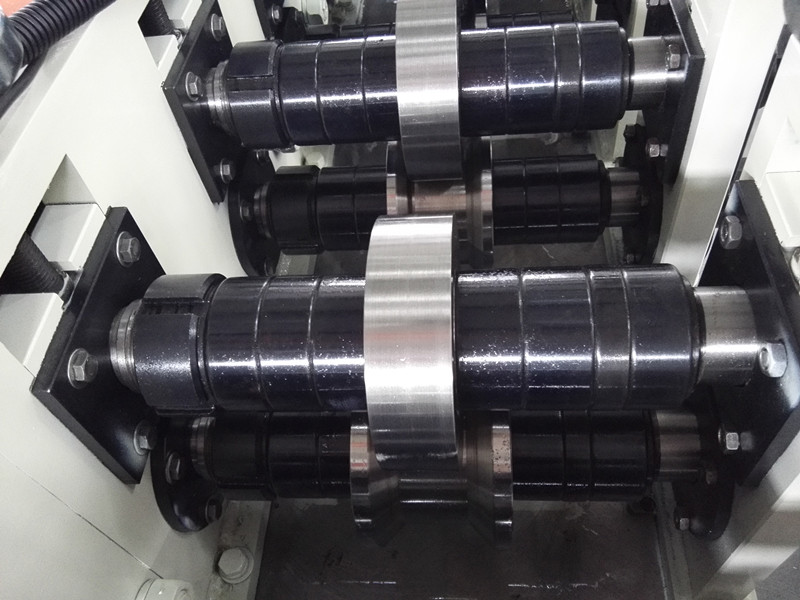

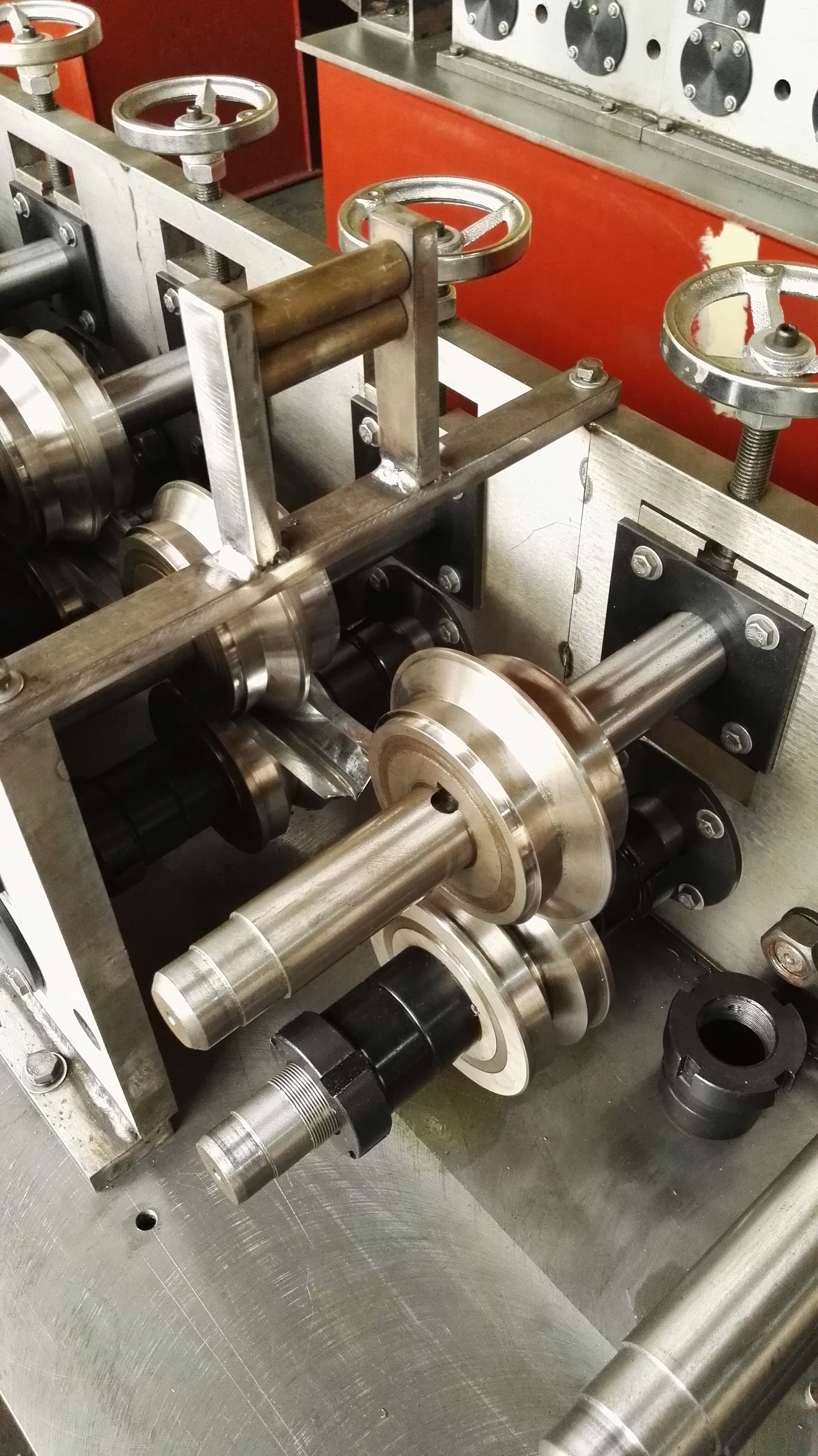

| Rollers | 12 rows |

| Material of forming rollers | 45# steel with chromed |

| Shaft diameter and material | 40mm, material is 40Cr |

| Controlling system | PLC |

| Cutting mode | Servo tracking cutting |

| Material of cutting blade | Cr12 mould steel with quenched treatment |

| Voltage | 380V/3Phase/50Hz or at your requirement |

| Main motor power | 4KW |

| Hydraulic station power | 3KW |

| Way of driven | Gear box |

Pictures of machine:

Product detail pictures:

Related Product Guide:

Fast and fantastic quotations, informed advisers to help you choose the correct products that suits all your needs, a short manufacturing time, responsible good quality control and distinct companies for paying and shipping affairs for OEM/ODM Factory Mesh Welding Machine - Double out light keel roll forming machine – Yingyee, The product will supply to all over the world, such as: Morocco, Morocco, South Korea, With the development and enlargement of mass clients abroad, now we've set up cooperative relationships with many major brands. We've our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost items and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.