OEM Manufacturer Steel Wire Straighten And Cutting Machine - Metal Hat Light Steel Keel Machine – Yingyee

Short Description:

OEM Manufacturer Steel Wire Straighten And Cutting Machine - Metal Hat Light Steel Keel Machine – Yingyee Detail:

Basic Info

Control System:PLC

Delivery Time:30 Days

Warranty:12 Months

Material Of Cutting Blade:Cr12

Cutting Mode:Servo Tracking Cutting

Type:Steel Frame & Purlin Machine

After Service:Engineers Available To Service Machinery Overseas

Forming Speed:30-40m/min(excluding Punching)

Voltage:380V/3Phase/50Hz Or At Your Request

Way Of Driven:Chain Or Gear Box

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

HS Code:84552210

Port:Tianjin Xingang

Product Description

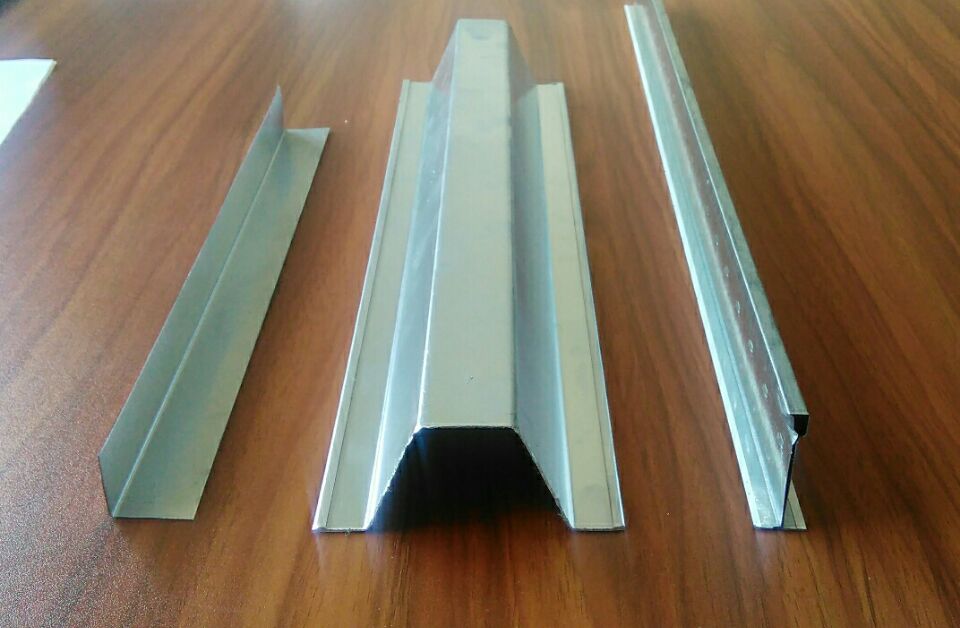

Metal Hat Light Steel Keel Machine

The combination of two sets of machines is just for making the machine smaller and taking small space. When letting two machines working, it is much easier to watch and operate. The two different drawing profiles could be made at the same time. The combination is random, they are could be wall angel roll forming machine, C stud roll forming machine, U track machine and others.

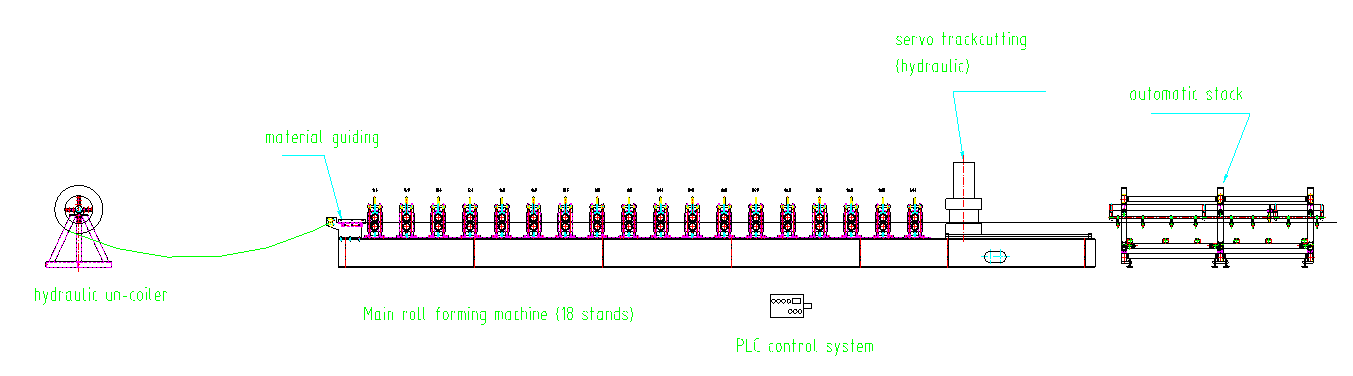

Working process:

Decoiler – Feeding guide – Straighteing – Main roll forming machine – PLC control system – Servo tracking cutting – Receiving table

Technical parameters:

| Raw material | PPGI, GI, Aluminum coils |

| Material thickness range | 0.3-1mm |

| Forming speed | 30-40m/min(without punching) |

| Rollers | 12 rows |

| Material of forming rollers | 45# steel with chromed |

| Shaft diameter and material | 40mm, material is 40Cr |

| Controlling system | PLC |

| Cutting mode | Servo tracking cutting |

| Material of cutting blade | Cr12 mould steel with quenched treatment |

| Voltage | 380V/3Phase/50Hz or at your requirement |

| Main motor power | 4KW |

| Hydraulic station power | 3KW |

| Way of driven | Gear box |

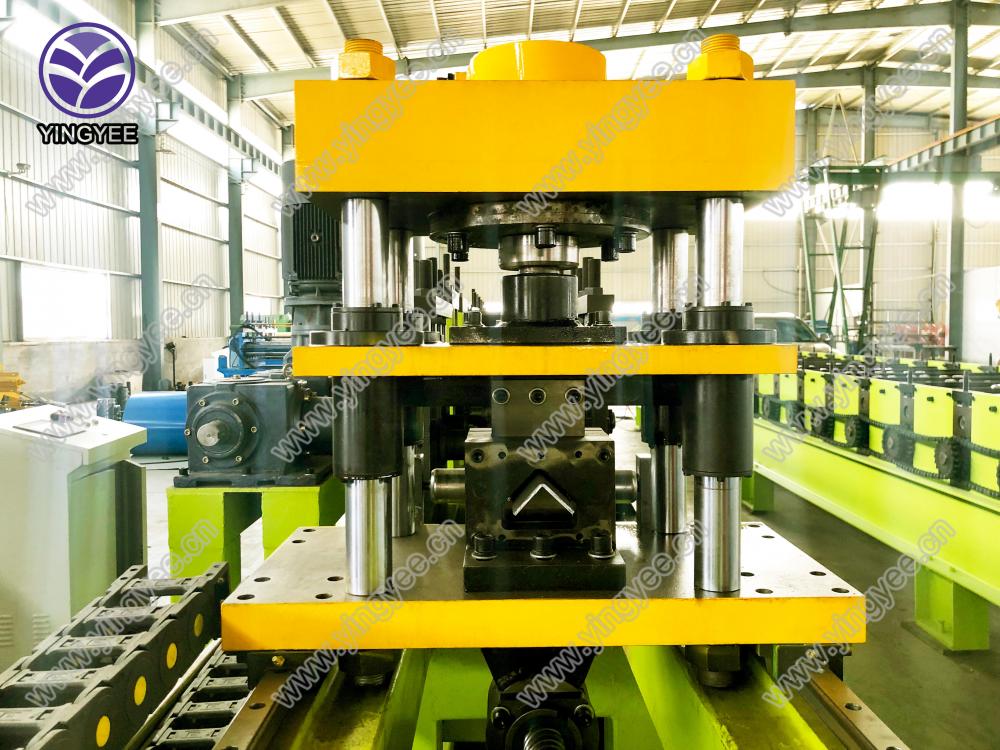

Pictures of machine:

Looking for ideal Hat Keel Rolling Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Hat Light Keel Roll Forming Machine are quality guaranteed. We are China Origin Factory of Celling Light Steel Keel Making Machine. If you have any question, please feel free to contact us.

Product Categories : Light Keel Roll Forming Machine > Omega Light Keel Forming Machine

Product detail pictures:

Related Product Guide:

We're commitment to offer you the aggressive cost ,superb products and solutions top quality, too as fast delivery for OEM Manufacturer Steel Wire Straighten And Cutting Machine - Metal Hat Light Steel Keel Machine – Yingyee, The product will supply to all over the world, such as: Orlando, Spain, Latvia, Our company warmly invites domestic and overseas customers to come and negotiate business with us. Allow us to join hands to create a brilliant tomorrow! We've been looking forward to cooperating with you sincerely to achieve a win-win situation. We promise to try our best to deliver you with high quality and efficient services.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.