OEM Manufacturer China Metal Sheet Roofing Glazed Steel Tile Roll Forming Machine

Short Description:

Together with the “Client-Oriented” company philosophy, a rigorous high-quality regulate program, sophisticated producing gear and a solid R&D staff, we constantly deliver premium quality solutions, superb products and services and aggressive price ranges for OEM Manufacturer China Metal Sheet Roofing Glazed Steel Tile Roll Forming Machine, We sincerely welcome consumers from both at home and overseas to come to negotiate company with us.

Together with the “Client-Oriented” company philosophy, a rigorous high-quality regulate program, sophisticated producing gear and a solid R&D staff, we constantly deliver premium quality solutions, superb products and services and aggressive price ranges for China Roof Tile Roll Forming Machine, Glazed Tile Forming Machine, We supply expert service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound solutions with good logistics service and economical cost. Depending on this, our solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

Basic Info

Model No.:YINGYEE015

Warranty:12 Months

Production Time:30 Days

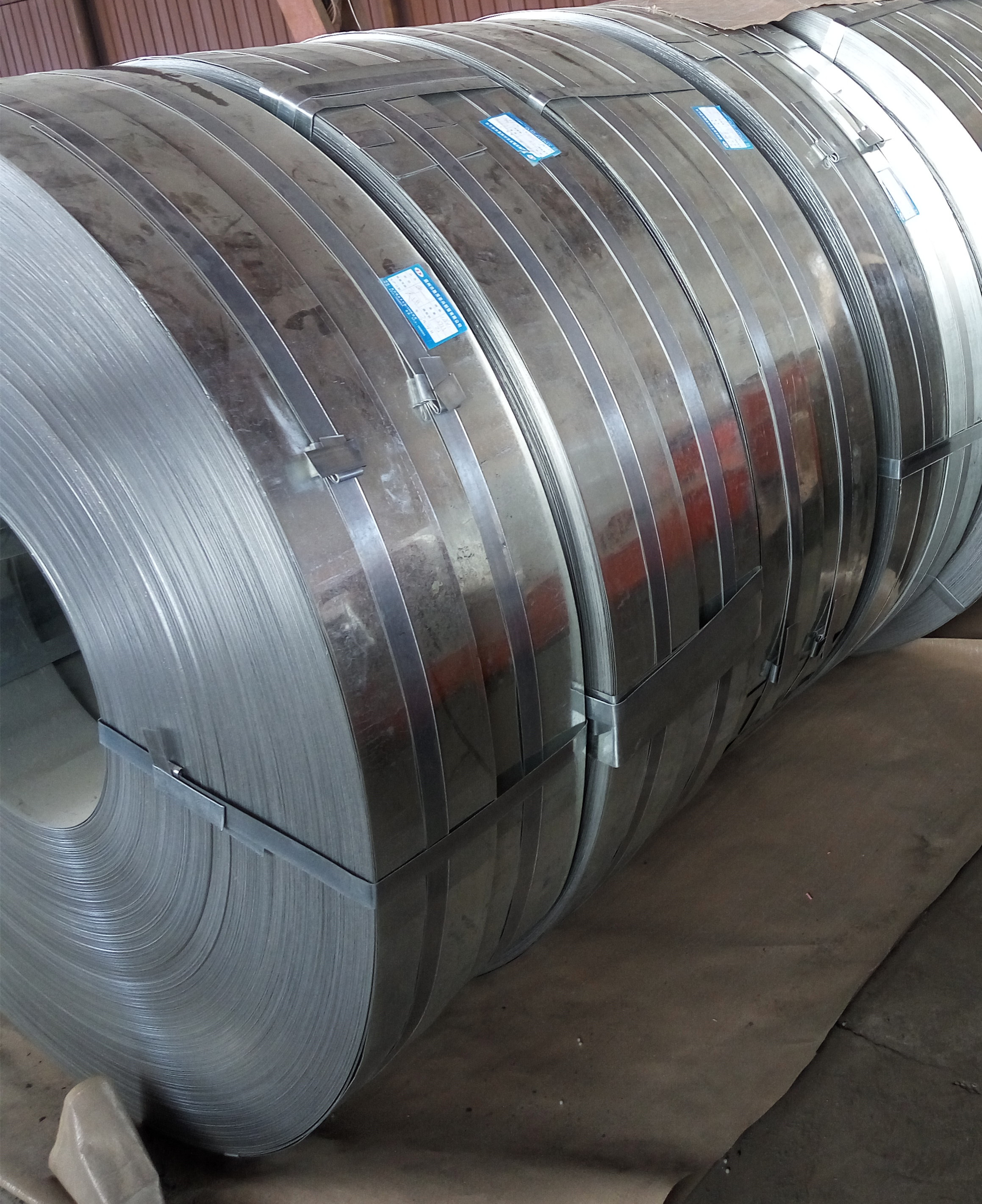

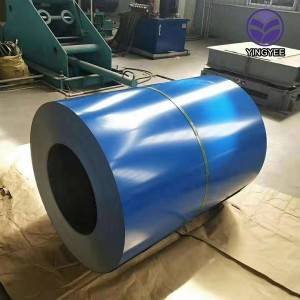

Material:Galvanized Coil

Width (mm):1000/1200/1250

Delivery Time:Within 15 Days

Galvanized Quantity:40g

Products Used For:Square Tube,round Tube, Strips,Galvanized Steel Coils & Steel Sheets

Using:Roof,wall, Deck, Ceiling

Additional Info

Packaging:NUDE

Productivity:1000000 ton/month

Brand:YY

Transportation:Ocean,Land

Place of Origin:Hebei

Supply Ability:200 ton/week

Certificate:CE/ISO9001

HS Code:84552210

Port:Tianjin,Shanghai,Qingdao

Product Description

Steel material galvanized coil delivery time 15 days

Galvanized Steel Coils is defined as a carbon steel sheet coated with zinc on both sides. Continuous hot dipping, or electro-galvanizing are the two processes used to produce Prepainted Galvanized Steel Coils & Steel Sheets. Generally speaking, the hot dip process consists of passing the steel through a bath of molten zinc. The electro-galvanizing process consists of the application of zinc by electrolytic disposition. The result is a layer of zinc tightly adhering to the base metal through an iron-zinc bonding layer. Our hot-dipped galvanized products are manufacturerd to ASTM A653 specifications while our electrogalvanized products conform to ASTM A879 specifications.

Pictures of product: