OEM Factory for Metal Stud And Track Roll Forming Machine - Roof Sheet Standing Seam Making Machine – Yingyee

Short Description:

OEM Factory for Metal Stud And Track Roll Forming Machine - Roof Sheet Standing Seam Making Machine – Yingyee Detail:

Basic Info

Control System:PLC

Delivery Time:30 Days

Warranty:12 Months

Material Of Cutting Blade:Cr12

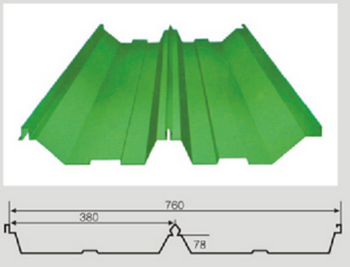

Using:Roof

Type:Roof Sheet Roll Forming Machine

Cutting Mode:Hydraulic

Material:Colored Steel, Galvanized Steel, Aluminum Steel

Forming Speed:15-20m/min

Voltage:At Customer’s Request

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

Product Description

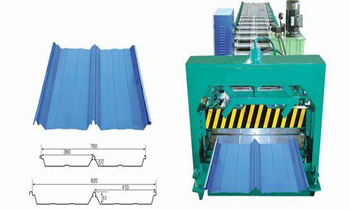

Roof Sheet Standing Seam Making Machine

Cold formed steel frame prefab steel structure building interlocking standing seam profile roll formed machine is the special equipment for continuous rolling and cold-forming on steel sheet

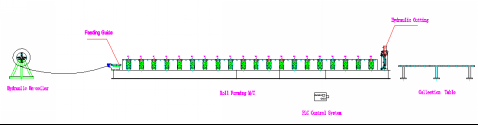

Working Flow:

Decoiler – Feeding Guide – Main Roll Forming Machine – PLC Contol System – Hydraulic Cutting – Output Table

Technical parameters:

| Raw material | Pre-painted coils, Galvanized coils, Aluminum coils |

| Material thickness range | 0.2-1mm |

| Rollers | 12-20 rows |

| Material of rollers | 45# steel with chromed |

| Shaft diameter and material | 70mm, material is 40 Cr |

| Forming speed | 10-15m/min |

| Material of cutter blade | Cr12 mould steel with quenched treatment 58-62℃ |

| Main motor power | 4KW |

| Hydraulic motor power | 3KW |

| Voltage | 380V/3Phase/5Hz |

| Total weight | about 3 tons |

| Controlling system | Omron PLC |

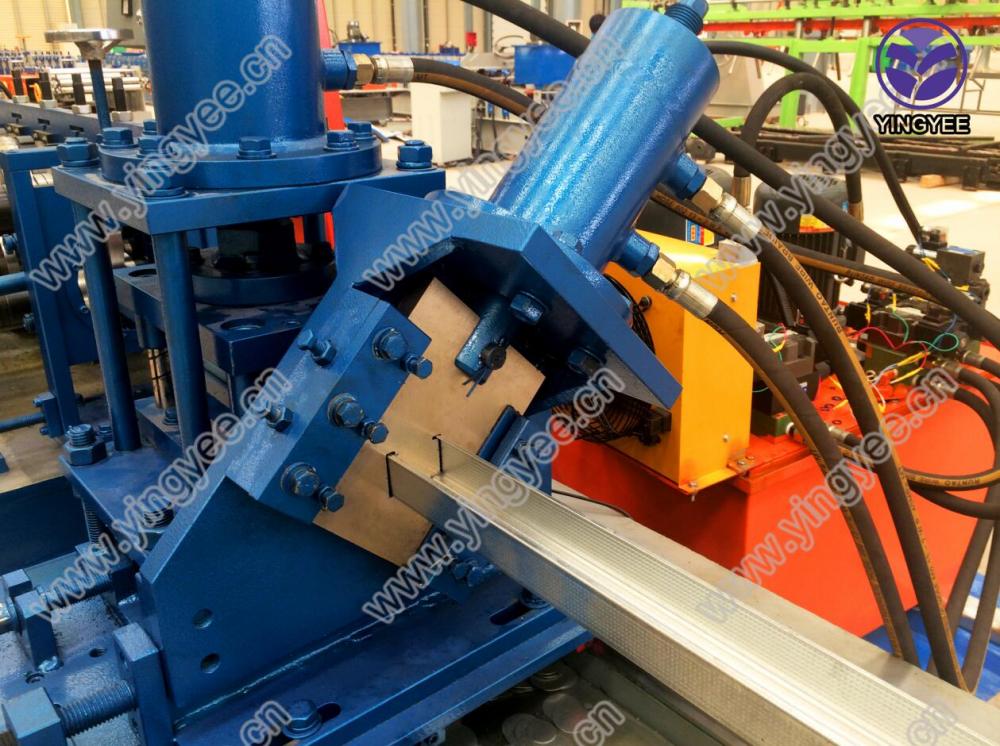

Pictures of machine:

Product detail pictures:

Related Product Guide:

The very rich projects management experiences and one to one service model make the high importance of business communication and our easy understanding of your expectations for OEM Factory for Metal Stud And Track Roll Forming Machine - Roof Sheet Standing Seam Making Machine – Yingyee, The product will supply to all over the world, such as: Florence, Durban, Nepal, Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality products. Our business aims to "honest and trustworthy, favorable price, customer first", so we won the trust of the majority of customers! If you are interested in our products and services, please do not hesitate to contact us!

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.