Roll forming machines are an essential part of the manufacturing process for building materials. These machines use steel coils to create a variety of building components, such as roofing panels. The roll forming process involves feeding a continuous strip of metal through a series of rollers to gradually shape the material into the desired shape. This article will explore the working principles of roll forming machines and their applications in the production of building materials.

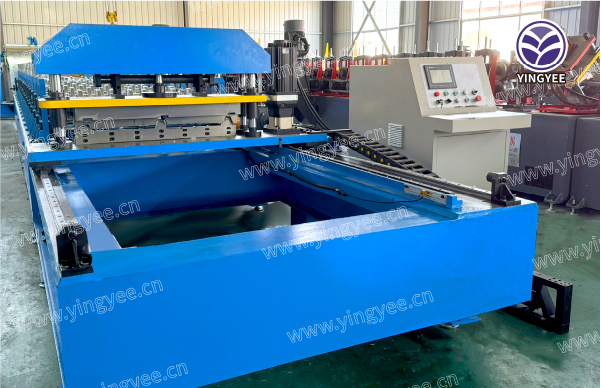

The roll forming machine consists of a series of rollers, each with a specific profile that gradually bends the steel coil into the desired shape. The steel coil is fed into the machine, and as it passes through the rollers, it undergoes a series of bending and forming operations. The rollers are strategically positioned to bend the metal at precise angles, resulting in a continuous, uniform profile. The entire process is automated, with the machine’s controls adjusting the roller positions and speeds to achieve the desired shape.

One of the key advantages of roll forming machines is their ability to efficiently produce long lengths of building components with consistent quality. The use of steel coils as the raw material allows for cost-effective production and enables manufacturers to create a wide range of profiles to meet different building requirements.

The applications of roll forming machines in the production of building materials are diverse. Roofing panels, for example, are commonly manufactured using roll forming machines.

Post time: Jun-03-2024