Specification

|

1

|

Suitable to process

|

Color steel plate, galvanized sheet, aluminum coils and etc.

|

|

2

|

Width of the feeding material

|

914-1250mm

|

|

3

|

Roller station

|

11-18 rows or custom as customer’s requirements

|

|

4

|

Thickness of feeding material

|

0.3-0.8mm

|

|

5

|

Productivity

|

0-15-30m/min

|

|

6

|

Rollers’ material

|

45# steel

|

|

7

|

Diameter of shaft

|

70-80mm

|

|

8

|

Voltage

|

380V 50Hz 3phases

|

|

9

|

Wall thickness of main forming machine

|

12-18mm steel plate

|

|

10

|

Main forming machine body

|

300-400 mm H steel

|

|

11

|

Motor power

|

4-7.5 kw

|

|

13

|

Weight

|

About 5-15T

|

|

14

|

Custom

|

According to customer’s requirements

|

LARGE CNC MILLING MACHINE

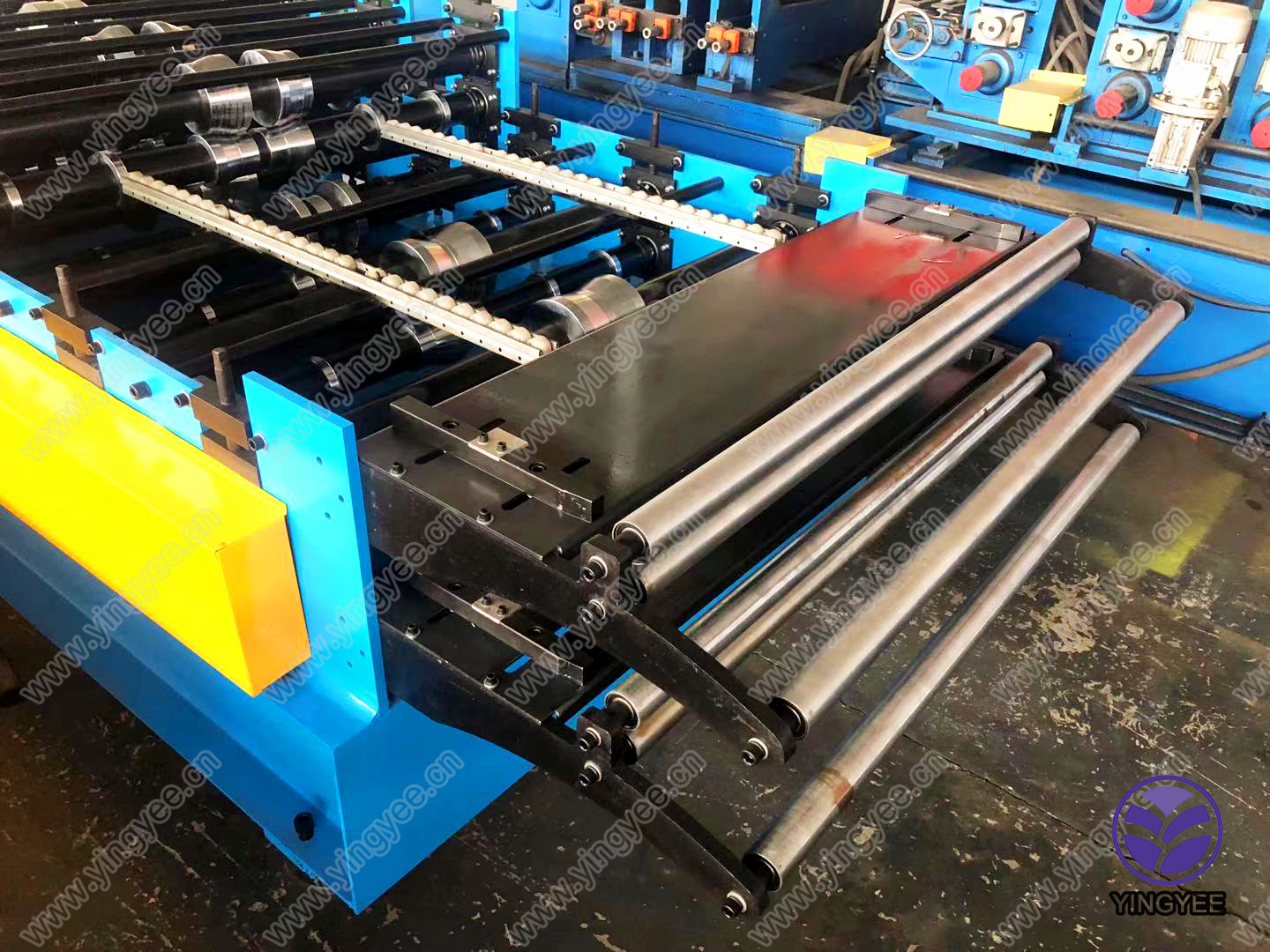

Combined double layer building material machinery steel tile roofing sheet roll forming machine a unique plant in Hebei Province.It directly mills the entire frame. The milling machine can make the machine’s large surface smoother and the machine is more perfect. Combined double layer building material machinery steel tile roofing sheet roll forming machine

SHOT BLASTING MACHINE

Combined double layer building material machinery steel tile roofing sheet roll forming machine can handle the entire machine frame or parts,making the rusty surface clean and smooth The surface of the product increases adhesion. Combined double layer building material machinery steel tile roofing sheet roll forming machine

Mechanical process

Combined double layer building material machinery steel tile roofing sheet roll forming machine line, have high precious CNC grinders and milling machines,to make the rollers and shafts of the machine.After produce, have professional engineer to check if these are qualified.

Post time: Sep-15-2022