Newly Arrival Gutter Cold Roll Forming Machine - Glazed Tile Roof Panel Machine with gear box – Yingyee

Short Description:

Newly Arrival Gutter Cold Roll Forming Machine - Glazed Tile Roof Panel Machine with gear box – Yingyee Detail:

Type:Roof Sheet Roll Forming Machine

Using:Roof

Material:PPGI, GI, Aluminum Coils

Cutting Mode:Hydraulic

Driven way: By Gear Box

Material Of Cutting Blade:Cr12 Mould Steel With Quenched Treatment

Control System:PLC

Voltage:380V/3Phase/50Hz Or At Customer’s Request

Warranty:12 Months

Delivery Time:30 Days

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

Product Description

Glazed Tile Roof Panel Machine

Glazed tile steel roofing machine can produce different shapes of steel roof by different roof panel machines, wall sheets according to the clients’ profile drawings and requirement. Metal Glazed Tile Machine is new building materials with various thickness and colors. Glazed tile steel roofing machine has many advantages, such as low cost, easy installation, short building period, re-cycle use, beautiful appearance, and are light weight but high strength.

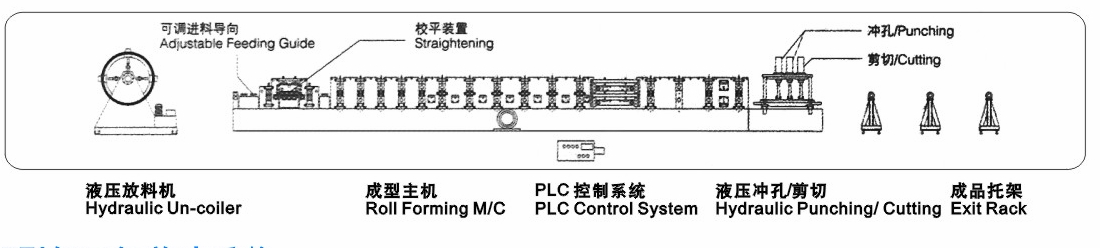

Working Flow: Decoiler – Feeding Guide – Straightening – Main Roll Forming Machine – PLC Contol System – Press – Hydraulic Cutting – Output Table

Technical parameters:

| Raw material | Colored steel, Galvanized steel, Aluminum steel |

| Material thickness range | 0.2-0.8mm |

| Rollers | 13 rows(according to drawings) |

| Material of roller | 45# steel with chromed |

| Forming speed | 15-20m/min(excluding press) |

| Shaft material and diameter | 75mm, material is 40Cr |

| Type of forming machine | single station with chain transmission |

| Controlling system | PLC & Transducer(Mitsubishi ) |

| Type of cutitng | Hydraulic cutting |

| Material of cutting blade | Cr12Mov with quench HRC58-62° |

| Voltage | 415V/3Phase/50Hz(or at buyer’s requirements) |

| Main motor power | 7.5KW |

| Hydraulic station power | 3KW |

Pictures:

Product detail pictures:

Related Product Guide:

To become the stage of realizing dreams of our employees! To build a happier, more united and extra professional workforce! To reach a mutual advantage of our prospects, suppliers, the society and ourselves for Newly Arrival Gutter Cold Roll Forming Machine - Glazed Tile Roof Panel Machine with gear box – Yingyee, The product will supply to all over the world, such as: Seychelles, Iran, Romania, As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.