New Arrival China Stud And Track Drywall Forming Machine - Aluminium Metal Roof Ridge Cap Roll Forming Machine – Yingyee

Short Description:

New Arrival China Stud And Track Drywall Forming Machine - Aluminium Metal Roof Ridge Cap Roll Forming Machine – Yingyee Detail:

Basic Info

Type:Roof Sheet Roll Forming Machine

Warranty:12 Months

Delivery Time:30 Days

Using:Roof

Cutting Mode:Hydraulic

Material Of Cutting Blade:Cr12

Control System:PLC

Material:Colored Steel, Galvanized Steel, Aluminum Steel

Forming Speed:15-20m/min(without Press)

Voltage:At Customer’s Request

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

Product Description

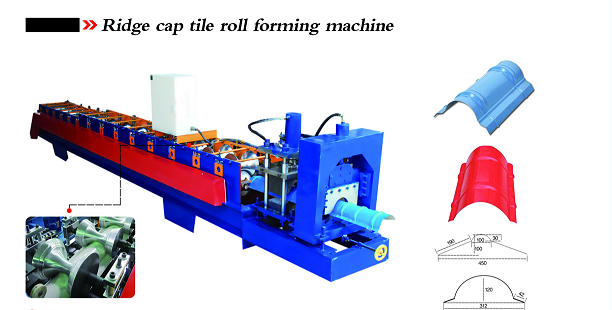

Ridge Cap Tile Roll Forming Machine

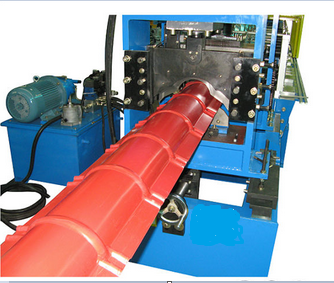

Aluminum Ridge Cap Roll Forming Machine, Different Profiles With Different Patterns Are Available According To The Customer`s Requirement & Such Ridge Cap Be Widely Used For House Building And Construction Field. And The Compact Design Can Try The Best To Save Space And Cost For Our Customers. The Machine Can Be Adjustable Between Different Ridge Cap With Automatically

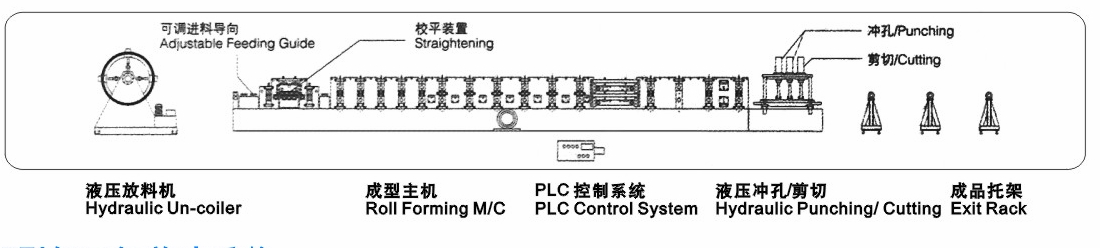

Working Flow: Decoiler – Feeding Guide – Straightening – Main Roll Forming Machine – PLC Contol System – Press – Hydraulic Cutting – Output Table

Technical parameters:

Raw material

Colored steel, Galvanized steel, Aluminum steel

Material thickness range

0.25-0.8mm

Rollers

16 rows(according to drawings)

Material of rollers

45# steel with chromed

Shaft diameter and diameter

60mm, material is 40Cr

Cutting mode

Hydraulic

Material of cutting blade

Cr12Mov with quench HRC58-62°

Forming speed

15-20m/min(without press)

Controlling system

PLC

Main motor power

7.5KW

Hydraulic station power

3KW

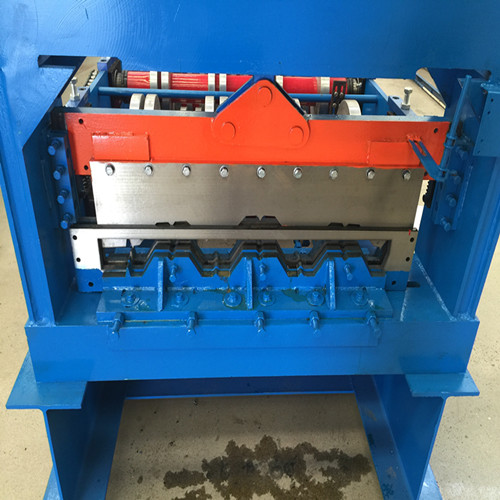

Pictures of machine:

Company information:

YINGYEE MACHINERY AND TECHNOLOGY SERVICE CO.,LTD

YINGYEE is the manufacturer specialized in various cold forming machineries and automatic production lines. We have a wonderful team with highly technology and excellent sales, which offer professional products and related service. We paid attention to quantity and after service, got great feedback and honor formal the clients. We have a great team for after service. We have sent several patch after service team to oversea to finish the products installation and adjustment. Our products were sold to more than 20 countries already. Also included US and Germany. Main product :

- Roof roll forming machine

- Roller Shutter Door Roll Forming Machine

- C and Z purlin roll forming machine

- Downpipe Roll Forming Machine

- Light Keel Roll Forming Machine

- Shearing Machine

- Hydraulic decoiler

- Bending machine

- Slitting machine

FAQ:

Training and Installation :

1. We offer installation service local in paid, reasonable charge.

2. QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service:

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period

2. Effective communication

3. Interface customized.

Looking for ideal Aluminum Ridge Cap Roll Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Ridge Cap Tile Forming Machine are quality guaranteed. We are China Origin Factory of Roof Tile Metal Sheet Machine. If you have any question, please feel free to contact us.

Product Categories : Roof Sheet Roll Forming Machine > Ridge Cap Tile Roll Forming Machine

Product detail pictures:

Related Product Guide:

We insist over the principle of enhancement of 'High high quality, Efficiency, Sincerity and Down-to-earth working approach' to offer you with superb assistance of processing for New Arrival China Stud And Track Drywall Forming Machine - Aluminium Metal Roof Ridge Cap Roll Forming Machine – Yingyee, The product will supply to all over the world, such as: Tunisia, Qatar, Brasilia, Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!