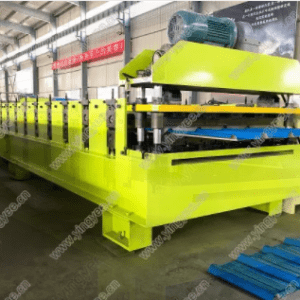

metal IBR roof sheet roll forming machine

Short Description:

Component:

Manual - coiler x1set l

Adjustable input equipment x1set l

Main roll forming machine with chromed plate x1set

Hydraulic cutting system x1set l

Hydraulic station x1set l

PLC Control system x1set l

Run-outtable x1set

Technical parameters

|

Manual Decoiler |

1: Max width of raw material :1300mm2: Capacity: 5000kgs3: Inner diameter of coil: 450-600mm |

|

Roll forming machine |

1.Matching material:PPGI/GI/Aluminium2.Material thickness:0.2-1mm3.Power:7.5kw4.Forming speed:0-30m/min5.The width of the plates:according to the drawings6.input leveling equipment:adjustable as photos.7.Roll stations:228.Shaft Material and diameter:materialis45#steel ¢80mm, 9.Tolerance:10m±1.5mm 10.Way of drive:chain with the motor

11.Controlling system:PLC 12.Voltage,Frequency,Phase:depend on customer request 13.Material of forming rollers:45#steel heat treatment and chromed 14Materialofcutterblade:Cr12mouldsteelwith quenched treatmentHRC58-62 15. Side plate:steel plate with Chromed. |

|

Cutting (hydraulic guide) |

1. Cutting motion: The main machine automatically stops and then cutting. After the cutting, the main machine will automatically start.2.Material of blade: Cr12 mould steel with quenchedtreatment58-62℃ 3.Length : Automatic length measuring4.Tolerance of length: 10+/- 1.5mm |

Picture

坐前面带出料.jpg)

坐前面带出料-300x225.jpg)

左前面带出料斜上-300x225.jpg)

左后面斜上-300x225.jpg)

右后面斜上-300x225.jpg)

成型产品效果-300x225.jpg)

切断部分电动切断-2-300x225.jpg)

前面带出料-300x225.jpg)

后面斜上-300x224.jpg)

坐前面带出料-300x225.jpg)

左前面带出料斜上-300x225.jpg)

后面斜上-300x224.jpg)

成型产品效果-300x225.jpg)

切断部分电动切断-2-300x225.jpg)

前面带出料-300x225.jpg)

右后面斜上-300x225.jpg)

左后面斜上-300x225.jpg)