Manufacturer of Downspout Roll Forming Machine - Color Steel Glazed Tile Forming Machine – Yingyee

Short Description:

Manufacturer of Downspout Roll Forming Machine - Color Steel Glazed Tile Forming Machine – Yingyee Detail:

Basic Info

Type:Roof Sheet Roll Forming Machine

Using:Roof

Material:PPGI, GI, Aluminum Coils

Forming Speed:15-20m/min(excluding Press)

Cutting Mode:Hydraulic

Material Of Cutting Blade:Cr12 Mould Steel With Quenched Treatment

Control System:PLC

Voltage:380V/3Phase/50Hz Or At Customer’s Request

Warranty:12 Months

Delivery Time:30 Days

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

Product Description

Color Steel Glazed Tile Forming Machine

Steel roofing machine glazed tile roof forming machine

Elegant appearance Glazed tile Roof Sheet Roll Forming Machine with high precision

Roof panel glazed tile products are formed by Cold Roll Forming Machine from high quality coated sheet, which performs the elegant style of traditional roof tile and suits for every architecture design. With light, strong strength and long lasting quality, it is convenient and takes short time for installation. Glazed Tile Roll Forming Machine is for continuously roll forming and pressing step tiles on series of product profile. The length can be set up or unlimited and the depth of each step is from 10 to 30mm adjustable.

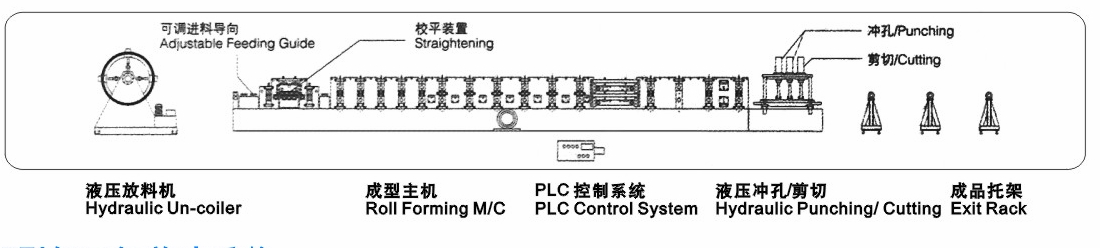

Working Flow: Decoiler – Feeding Guide – Straightening – Main Roll Forming Machine – PLC Contol System – Press – Hydraulic Cutting – Output Table

Technical parameters:

| Raw material | Colored steel, Galvanized steel, Aluminum steel |

| Material thickness range | 0.2-0.8mm |

| Rollers | 13 rows(according to drawings) |

| Material of roller | 45# steel with chromed |

| Forming speed | 15-20m/min(excluding press) |

| Shaft material and diameter | 75mm, material is 40Cr |

| Type of forming machine | single station with chain transmission |

| Controlling system | PLC & Transducer(Mitsubishi ) |

| Type of cutitng | Hydraulic cutting |

| Material of cutting blade | Cr12Mov with quench HRC58-62° |

| Voltage | 415V/3Phase/50Hz(or at buyer’s requirements) |

| Main motor power | 7.5KW |

| Hydraulic station power | 3KW |

Pictures:

FAQ:

Training and Installation :

1. We offer installation service local in paid, reasonable charge.

2. QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service:

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period

2. Effective communication

3. Interface customized.

Looking for ideal Roof Tile Making Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Glazed Tile Making Machine are quality guaranteed. We are China Origin Factory of Glazed Tiled Rolling Machine For Building. If you have any question, please feel free to contact us.

Product Categories : Roof Sheet Roll Forming Machine > Glazed Tile Roof Sheet Forming Machine

Product detail pictures:

Related Product Guide:

We have been convinced that with joint attempts, the business enterprise between us will bring us mutual benefits. We could guarantee you product or service good quality and aggressive value for Manufacturer of Downspout Roll Forming Machine - Color Steel Glazed Tile Forming Machine – Yingyee, The product will supply to all over the world, such as: Angola, Singapore, Cyprus, We'll continue to devote ourselves to market & product development and build a well-knit service to our customer to create a more prosperous future. Please contact us today to find out how we can work together.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.