Large Span Arch Sheet Roll Forming Machine

Short Description:

Basic Info

Tile Type:Colored Steel

Certification:CE, ISO

Condition:New

Customized:Customized

Usage:Roof, Wall, Floor

Transmission Method:Machinery

Products:Big Span Roll Forming Machine

Material:Pre-printed Steel Coil,galvanized Coil,Aluminum Co

Material Of The Cutting Blade:CR12

Speed:10-25m/min

Cutting Mode:Hydraulic

Control Mode:PLC

Voltage:As Customers Request

Additional Info

Packaging:NUDE

Productivity:CHINA

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200sets/years

Certificate:CE/ISO9001

HS Code:84552210

Port:Tianjin

Product Description

Large Span Arch Sheet Roll Forming Machine

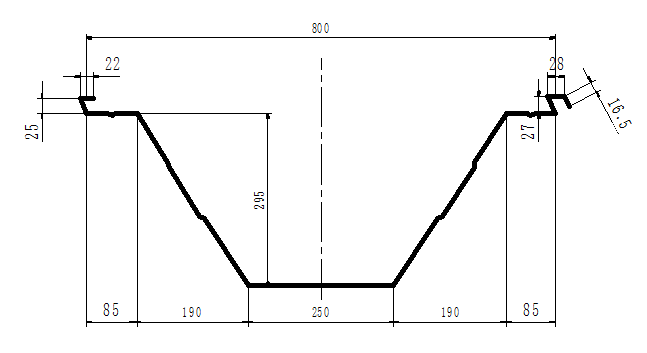

Specification:

1) Main machine dimension: 9.65m*2.23m*2.4m

2) Bending machine dimension; 3.8m*2.23m*2.4m

3) Suitable material: galvanized steel, colored steel, etc

4) Coil thickness: 0.6 –1.5mm

5) Roller stands:16

6) Roller diameter:80mm

7) Totally power:18.5kw

8) Main Power:7.5kw; Hydraulic power:4.0kw; side bending power:1.5kw*2

Curving power:4.0kw

9) Roller material: 40Cr

10) Shaft material: high grade #45 steel

11) Cutting Blade material:Cr12 steel

12) Machine speed: forming speed 13m/min, Seaming speed:6m/min

13) Span : ≤38m

14) Power supply: AC380V±10%, 50Hz, or as per your requirement

Industrial Process And Component Specification

Component Specification

1. Manual Uncoiler:

Usage: It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand.

Loading capacity: 5T

Inner diameter: 500-508mm

2. Feeding Table:

Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat. Parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

3. Main Roll Forming Machine:

Material of rollers: 45# steel, roller surfaces polishing, hard plating. The polished surface and the heat treatment towards the molds also can keep the molding. Plate surface smooth and not easy to be marked when it is being stamped

4. Hydraulic System:

Power: 11KW, Hydraulic oil:40#.

Hydraulic oil into the hydraulic oil tank, the pump drives the cutter machine to begin the cutting job.

5. Shearing Mechanism: It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Material of blades: Cr12, quenching treatment.

6. Computer Control Cabinet: The target piece`s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use. Plc: EURA

Main product :

Roof roll forming machine

- Roller Shutter Door Roll Forming Machine

- C and Z purlin roll forming machine

- Downpipe Roll Forming Machine

- Light Keel Roll Forming Machine

- Guardrail Roll Forming Machine

- Storage roll forming machine

- Cable Tray Roll Forming Machine

- Shearing Machine

- Hydraulic decoiler

- Bending machine

- slitting machine

Looking for ideal Color Large Span Roofing Making Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Kspan Roof Sheet Machine are quality guaranteed. We are China Origin Factory of Long Span Roofing Making Machine. If you have any question, please feel free to contact us.

Product Categories : Long Span Roll Forming Machine