High definition Unistrut Channel Roll Forming Machine - C/Z purlin automatic line – Yingyee

Short Description:

High definition Unistrut Channel Roll Forming Machine - C/Z purlin automatic line – Yingyee Detail:

Basic Info

Model No.:C/Z

Type:Roof Sheet Roll Forming Machine

Warranty:12 Months

Material:Steel Coil, Galvanized, PPGI, Aluminum

Speed:10-18m/min(not Include Punching And Cutting Time)

Control System:Panasonic/Mitsubishi PLC

Way Of Driven:Chain Transmission

Cutting Mode:Hydraulic

Material Of Cutting Blade:CR12 Mov

Voltage:At Customer’s Request

Rollers Material:Gcr15 Or Cr12

Additional Info

Packaging:PLASTIC FILM, WOODEN CASE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean,Land,Air

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

HS Code:84552210

Port:TIANJIN,XIAMEN,SHANGHAI

Product Description

C/Z Purlin Roll Forming Machine

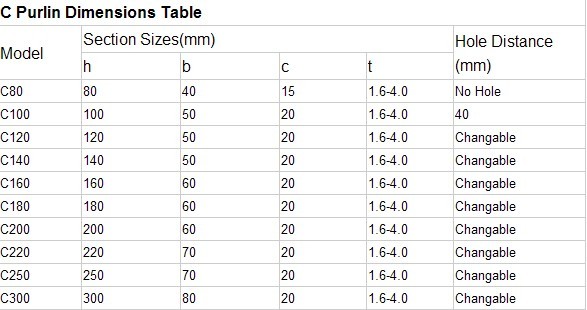

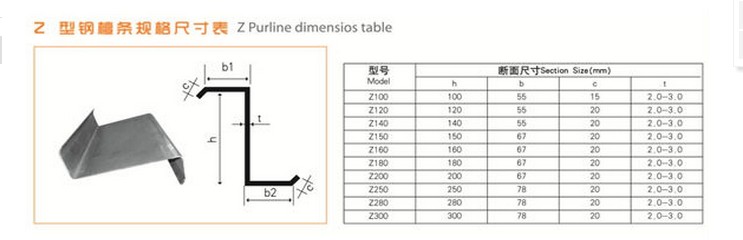

The structural C and Z purlins are for industrial buildings, anywhere that strong reliable steel framing is required. Manufactured from quality galvanised steel, this is a fully integrated system allowing for flexible design options.

Our machine is the best choice in rollforming machines for the C-Channel, Lipped Channel, Z-shaped profiles.

The machine adjust size of c/z by PLC automatic type. for c u to z change can be finished in two minute.

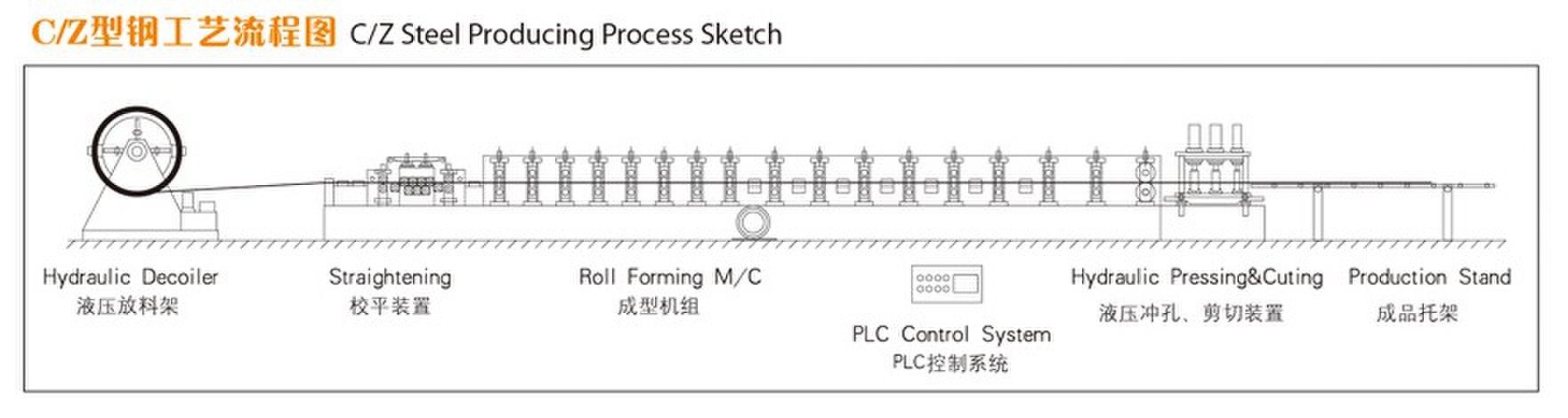

Working Flow: Decoiler – Feeding Guide – Main Roll Forming Machine – PLC Contol System – Hydraulic Punching- Hydraulic Cutting – Output Table

Technical parameters:

| Matching material | Steel coil, Galvanized, PPGI, Aluminum |

| Material thickness range | According to drawings |

| Main motor power | 30W |

| Forming speed | 10-18min (not include punching and cutting time) |

| Hydraulic power | 7.5KW |

| Quantity of rollers | About 18 |

| Shaft diameter and material | 70mm, material is 45#steel |

| Material of rollers | Gcr15 or Cr12 with chromed |

| Way of driven | chain transmission |

| Controlling system | PLC |

| Voltage | 380V/30Phase/50Hz (as customer require) |

| Total weight | About 12 tons |

| Size of the machine | L*W*H 10m*1.2m*1.6m |

Pictures of machine:

Company information:

YINGYEE MACHINERY AND TECHNOLOGY SERVICE CO.,LTD

YINGYEE is the manufacturer specialized in various cold forming machineries and automatic production lines. We have a wonderful team with highly technology and excellent sales, which offer professional products and related service. We paid attention to quantity and after service, got great feedback and honor formal the clients. We have a great team for after service. We have sent several patch after service team to oversea to finish the products installation and adjustment. Our products were sold to more than 20 countries already. Also included US and Germany. Main product :

- Roof roll forming machine

- Roller Shutter Door Roll Forming Machine

- C and Z purlin roll forming machine

- Downpipe Roll Forming Machine

- Light Keel Roll Forming Machine

- Shearing Machine

- Hydraulic decoiler

- Bending machine

- Slitting machine

FAQ:

Training and Installation :

1. We offer installation service local in paid, reasonable charge.

2. QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service:

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period

2. Effective communication

3. Interface customized.

Looking for ideal C Purlinroll Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Z Purlin Roll Forming Machine are quality guaranteed. We are China Origin Factory of C Z Automatic Roll Forming Machine. If you have any question, please feel free to contact us.

Product Categories : C/Z/U Purlin Changeable Roll Forming Machine

Product detail pictures:

Related Product Guide:

We have state-of-the-art equipment. Our products are exported for the USA, the UK and so on, enjoying a fantastic status among the clients for High definition Unistrut Channel Roll Forming Machine - C/Z purlin automatic line – Yingyee, The product will supply to all over the world, such as: Somalia, Libya, Oslo, Many kinds of different products are available for you to choose, you can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to provide more support for customers. Welcome all nice buyers communicate details of products with us!!

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.