Forming and Crimping Integrated Machine

Short Description:

Product Description

Steel downpipe roll former making machine

The Steel downpipe roll former making machine are divided into two categories: Square Tube Seamless Steel Pipe Roll Forming Machine and Welded Steel Pipe Roll Forming Machine.

According to the cross-sectional shape can be divided into Square Tube Roll Forming Machine and Roll Forming Machine, which are widely used in circular steel pipe, but there are some semi-circular, hexagonal, equilateral triangle, octagonal shaped steel pipe.

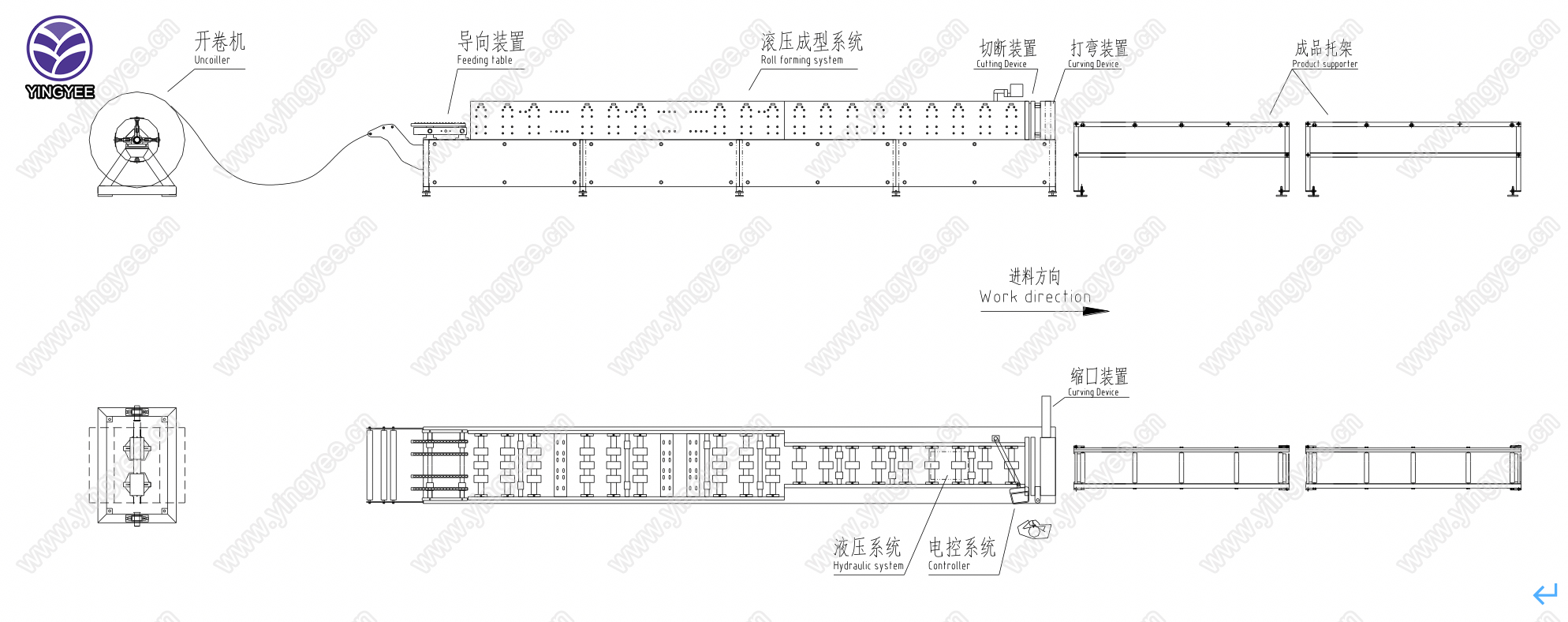

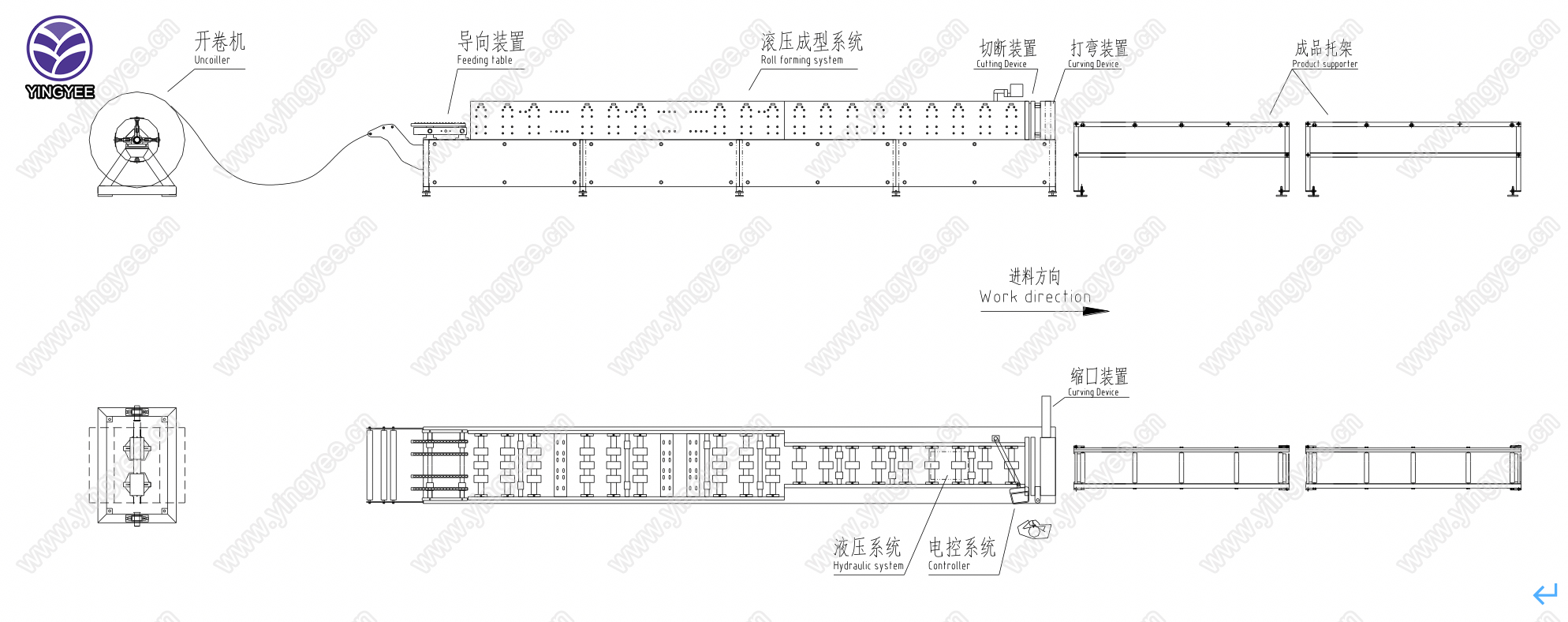

Working Flow: Decoiler – Feeding guide – Main Roll Forming Machine – PLC Contol System – Hydraulic Cutting and crimping – Output Table

Technical parameters:

| Raw material | PPGI or GI |

| Material thickness range | 0.2-0.8mm |

| Rollers | 18 rows |

| Material of forming rollers | 45# steel with chromed |

| Shaft diameter and mateiral | 76mm, material is 40Cr |

| Material of cutting blade | Cr12 mould steel with quenched treatment |

| Forming speed | 12-18m/min(excluding cutting stoping time) |

| Main motor power | 5.5 KW |

| Hydraulic station power | 3KW |

| Mode of cutting | Hydraulic cutting or flying saw cutting or mould cutting |

| Control system | PLC Frequency Control System with touch screen |

.jpg)

Send your message to us:

Write your message here and send it to us

-225x300.jpg)