Factory Promotional Steel Purling Roll Forming Machine - Metal Angle Roll Forming Machine – Yingyee

Short Description:

Factory Promotional Steel Purling Roll Forming Machine - Metal Angle Roll Forming Machine – Yingyee Detail:

Basic Info

Model No.:YY–ARM—002

Control System:PLC

Delivery Time:30 Days

Warranty:12 Months

Material Of Cutting Blade:Cr12

Type:Steel Frame & Purlin Machine

After Service:Engineers Available To Service Machinery Overseas

Voltage:380V/3Phase/50Hz Or At Your Request

Cutting Mode:Servo Tracking Cutting

Way Of Driven:Gear

Forming Speed:0-45m/min

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

HS Code:84552210

Port:Tianjin Xingang

Product Description

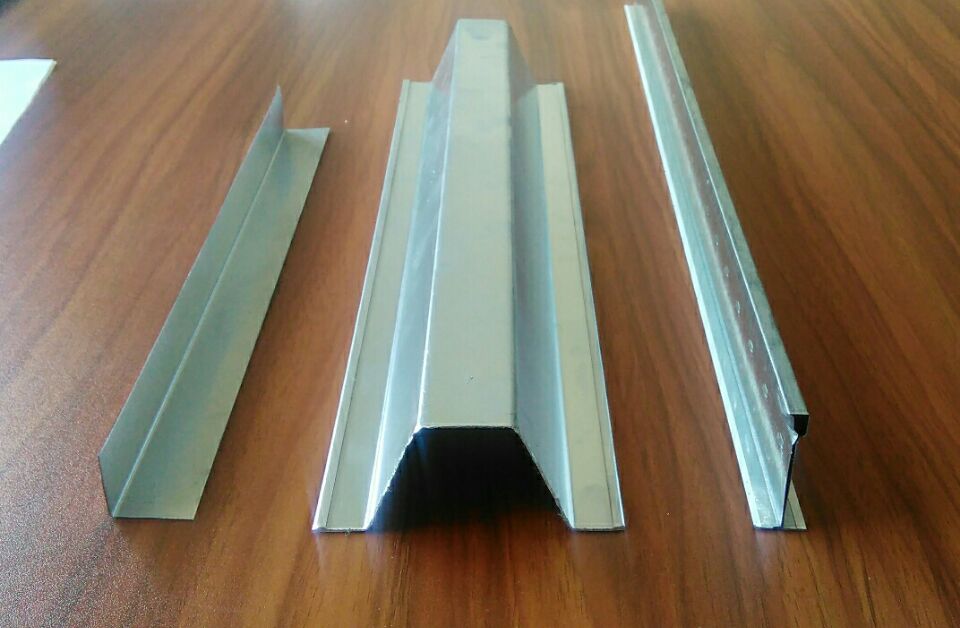

Metal Angle Roll Forming Machine

Metal ceiling Light Keel Roll Forming MachineCeiling Tee bar Making machine Light Keel roll forming machine

Angle Channel Machineis a strip of raw materials, through continuous cold rolling molding, production of complex cross-section profiles, Automatic Angle Roll Forming Machine consists of decoiler, guide rack, forming hosts, calibration device, cut-off part, receiving station, composed of electrical control and so on. Metal Angle Roll Forming Machine is easy to use, easy to operate and so on.

Working process:

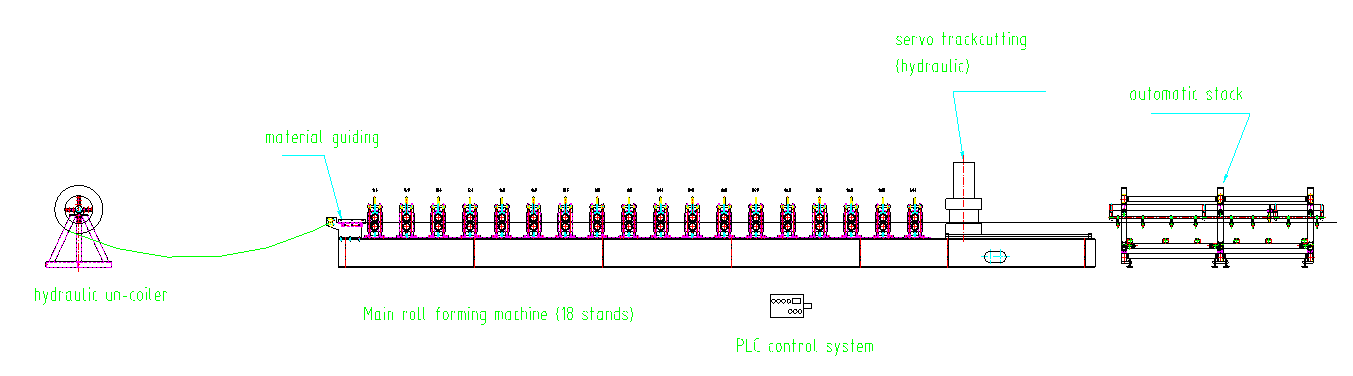

Decoiler – Feeding guide – Straighteing – Main roll forming machine – PLC control system – Servo tracking cutting – Receiving table

Technical parameters:

| Raw material | PPGI, GI, Aluminum coils |

| Material thickness range | 0.3-1mm |

| Forming speed | 0-45m/min(without punching) |

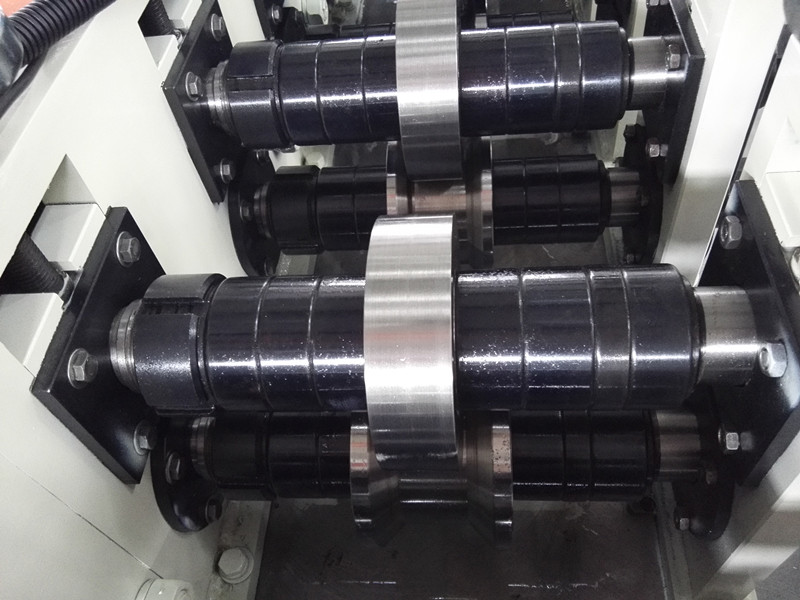

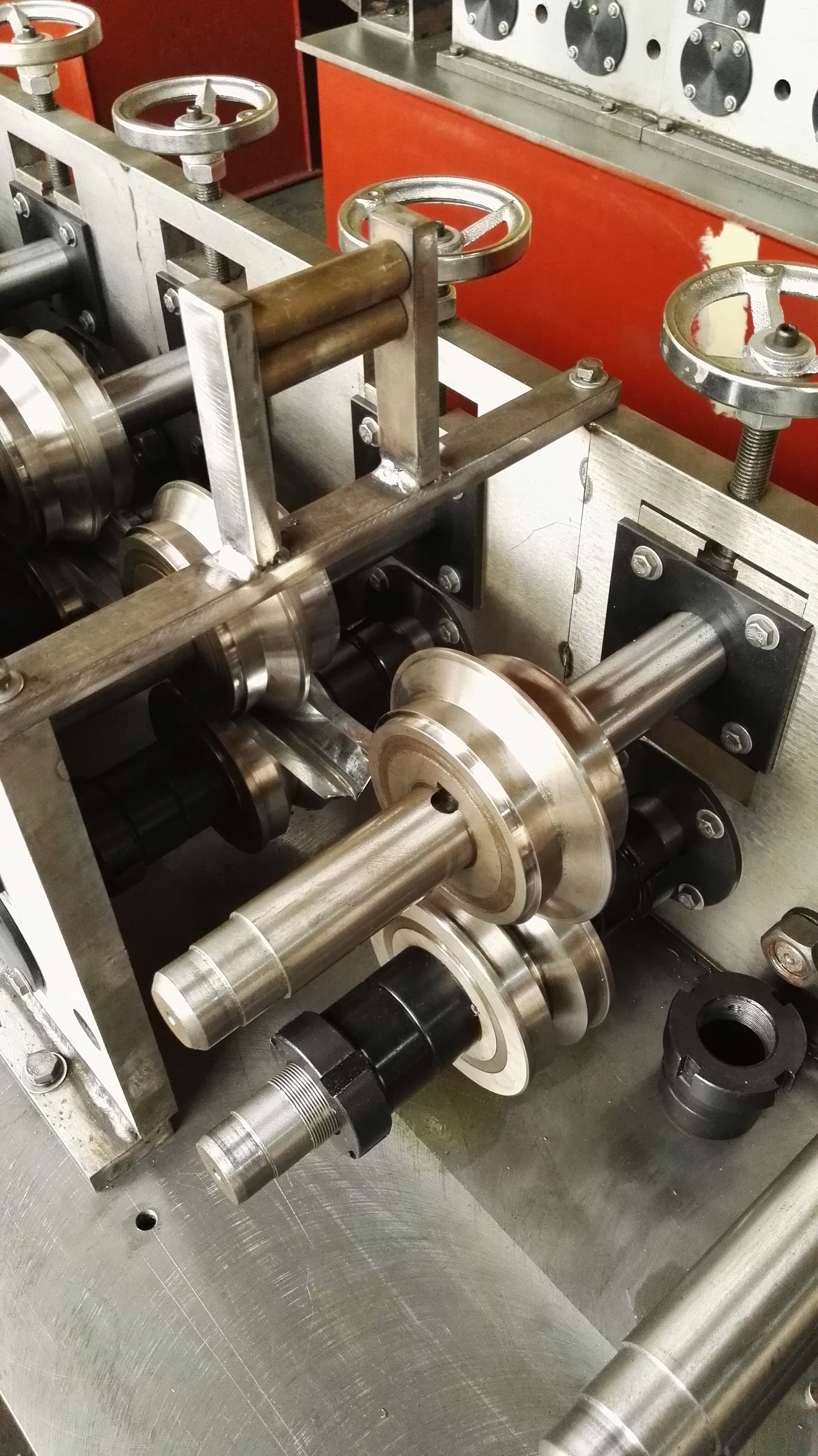

| Rollers | 12 rows |

| Material of forming rollers | 45# steel with chromed |

| Shaft diameter and material | 40mm, Cr12 |

| Controlling system | PLC |

| Cutting mode | Servo tracking cutting |

| Material of cutting blade | Cr12 mould steel with quenched treatment |

| Voltage | 380V/3Phase/50Hz or at your requirement |

| Main motor power | 5.5KW |

| Hydraulic station power | 3KW |

| Way of driven | Gear |

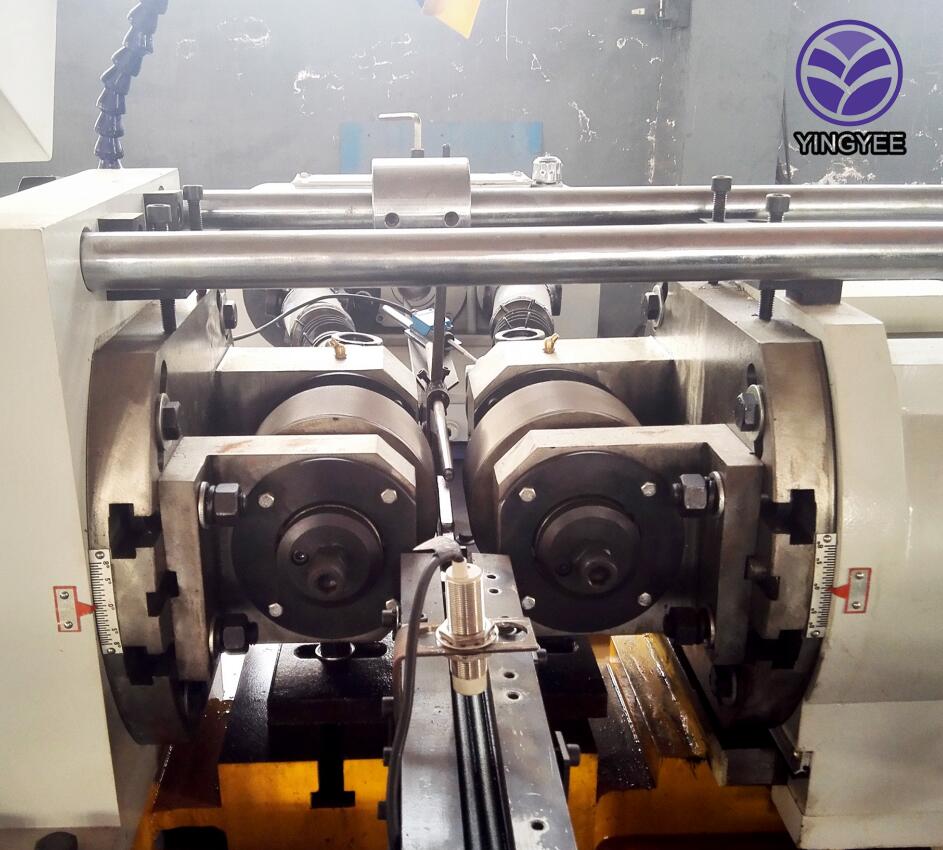

Pictures of machine:

Product detail pictures:

Related Product Guide:

We always follow the principle "Quality Very first, Prestige Supreme". We have been fully committed to delivering our customers with competitively priced high-quality products and solutions, prompt delivery and experienced services for Factory Promotional Steel Purling Roll Forming Machine - Metal Angle Roll Forming Machine – Yingyee, The product will supply to all over the world, such as: Johor, Las Vegas, Tunisia, Our company's main items are widely used all over the world; 80% of our products and solutions exported to the United States, Japan, Europe and other markets. All stuff sincerely welcome guests come to visit our factory.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.