Double Out Stud and Track/C Channel/Drywall/Gypsum Stud/Wall Angle Roll Forming Machine

Short Description:

Double-out light keel machines have two different model designs that can be made in one machine. That kind of design would save the cost of the machine and the space of the warehouse. It has the advantage of a lightweight, neat appearance. Such as metal studs and track roll-forming machines.

Basic Info

Control System: PLC

Delivery Time: 30 Days

Warranty: 12 Months

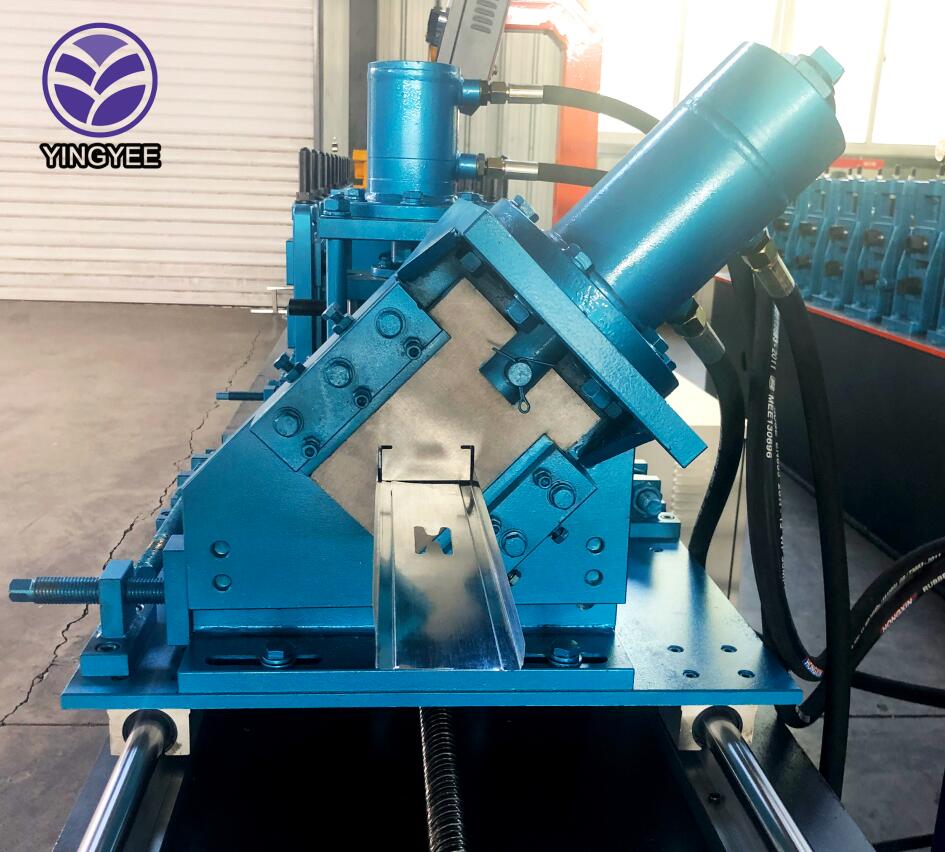

Material Of Cutting Blade: Cr12

Type: Steel Frame & Purlin Machine

After Service: Engineers Available To Service Machinery Overseas

Voltage: 380V/3Phase/50Hz Or At Your Request

Way Of Driven: Chain Or Gear Box

Forming Speed: 30-40m/min(excluding Punching)

Cutting Mode: Servo Tracking Cutting

Additional Info

Packaging: NUDE

Productivity: 200 sets/year

Brand: YY

Transportation: Ocean

Place of Origin: Hebei

Supply Ability: 200 sets/year

Certificate: CE/ISO9001

Product Description

Working process:

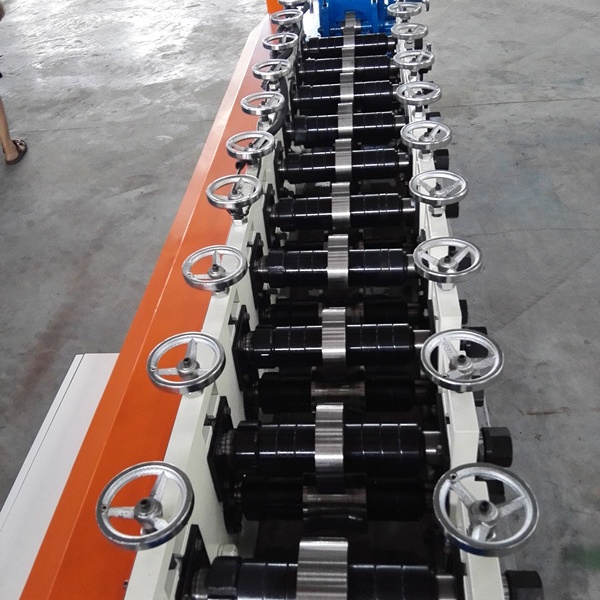

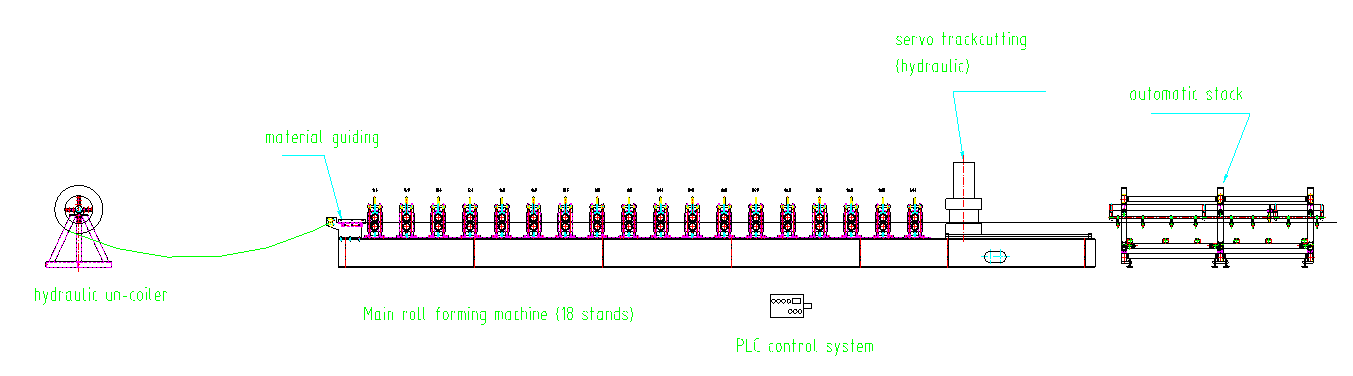

Decoiler - Feeding guide - Straightening - Main roll forming machine - PLC control system - Servo tracking cutting - Receiving table

Technical parameters:

| Raw material | PPGI, GI, Aluminum coils |

| Material thickness range | 0.3-1mm |

| Forming speed | 30-40m/min(without punching) |

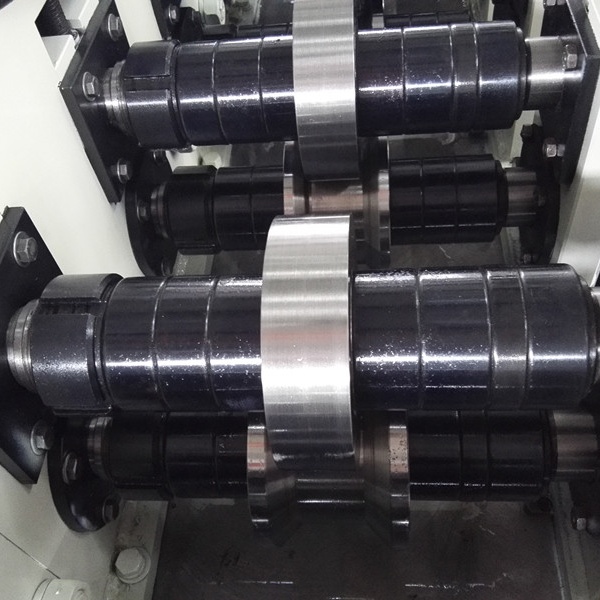

| Rollers | 12 rows |

| Material of forming rollers | 45# steel with chromed |

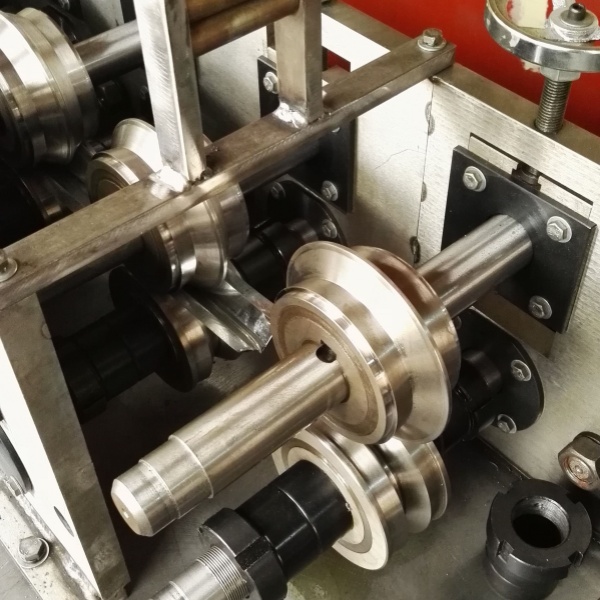

| Shaft diameter and material | 40mm, the material is 40Cr |

| Controlling system | PLC |

| Cutting mode | Servo tracking cutting |

| Material of cutting blade | Cr12 mold steel with quenched treatment |

| Voltage | 380V/3Phase/50Hz or at your requirement |

| Main motor power | 4KW |

| Hydraulic station power | 3KW |

| Way of driven | Gearbox |

Pictures of the machine: