China Factory for Deck Floor Roll Forming Machine - Galvanized Downspout Roll Forming Machine – Yingyee

Short Description:

China Factory for Deck Floor Roll Forming Machine - Galvanized Downspout Roll Forming Machine – Yingyee Detail:

Basic Info

Delivery Time:30 Days

Warranty:12 Months

Material Of Cutting Blade:Cr12

Forming Speed:25-30m/min

Material:GI, PPGI, Aluminum Coils

After Service:Engineers Available To Service Machinery Overseas

Voltage:380V/3Phase/50Hz Or At Your Request

Way Of Driven:Chain Or Gear Box

Type:Pipe Production Line

Cutting Mode:Flying Saw Cutting Or Mould Cutting

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

Product Description

Galvanized Downspout Roll Forming Machine

Factory best sale aluminium Downpipe Roll Forming Machine Rain gutter making machine mainly consists of uncoiler, roll forming system, cutting equipment, protective guard, hydraulic system, control system and out table. Galvanized Downspout Roll Forming Machine can make curve for down pipe to meet the requirement of practical engineering projects.

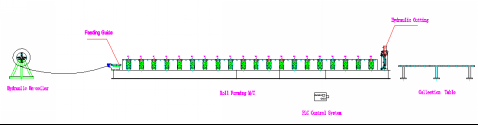

Working Flow: Decoiler – Feeding guide – Main Roll Forming Machine – PLC Contol System – Hydraulic Cutting – Output Table

Technical parameters:

| Raw material | PPGI, GI, Aluminum steel |

| Material thickness range | 0.2-0.8mm |

| Rollers | 18 rows |

| Material of forming rollers | 45# steel with chromed |

| Shaft diameter and mateiral | 76mm, material is 40Cr |

| Material of cutting blade | Cr12 mould steel with quenched treatment |

| Forming speed | 12-15m/min(excluding cutting stoping time) |

| Main motor power | 4 KW |

| Hydraulic station power | 3KW |

| Mode of cutting | Hydraulic cutting or flying saw cutting or mould cutting |

| Control system | PLC Frequency Control System with touch screen |

Pictures of machine:

FAQ:

Training and Installation :

1. We offer installation service local in paid, reasonable charge.

2. QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service:

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period

2. Effective communication

3. Interface customized.

Looking for ideal Factory Price Downspout Roll Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Roll Forming Machine Expo are quality guaranteed. We are China Origin Factory of Rain Gutter Roll Forming Machine. If you have any question, please feel free to contact us.

Product Categories : Downpipe Roll Forming Machine > Square Downspipe Roll Forming Machine

Product detail pictures:

Related Product Guide:

While in the past few years, our organization absorbed and digested innovative technologies both equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted for the advancement of China Factory for Deck Floor Roll Forming Machine - Galvanized Downspout Roll Forming Machine – Yingyee, The product will supply to all over the world, such as: Oman, Mexico, Qatar, Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to supply our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We have been ready to face the worries and make the improve to understand all the possibilities in international trade.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.