Bolt and Nut long span forming and bending machine

Short Description:

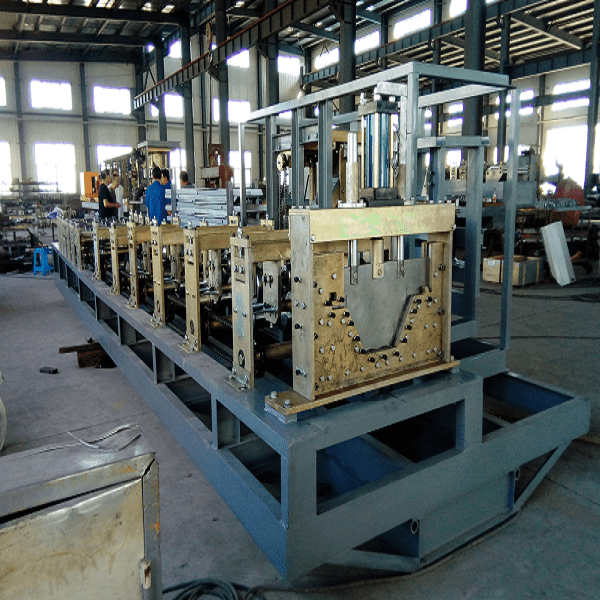

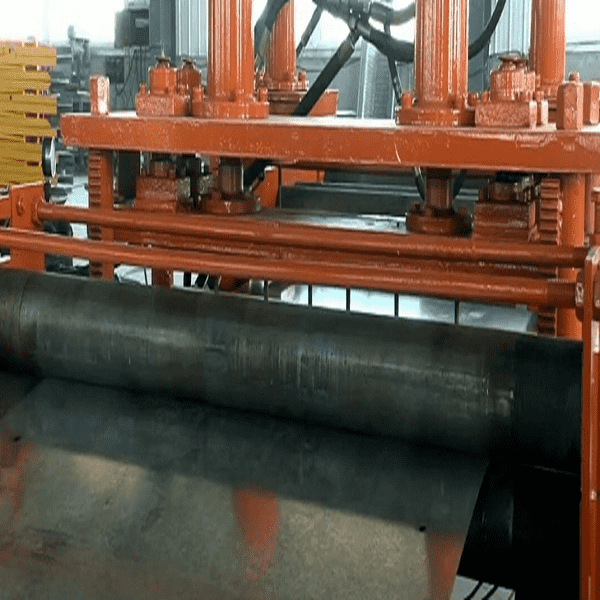

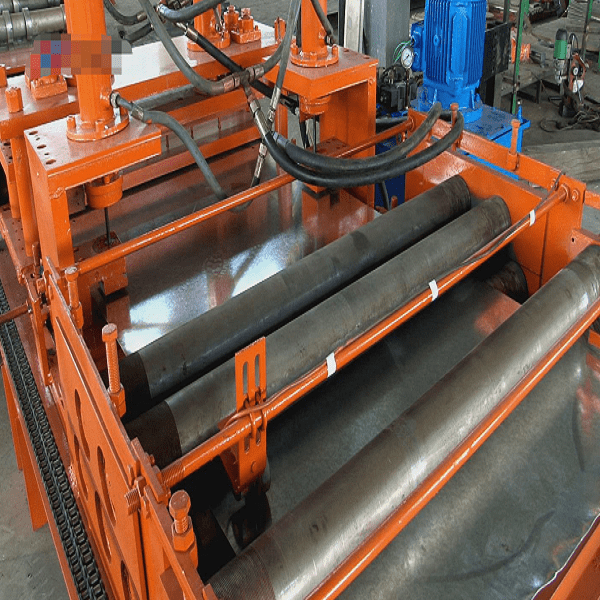

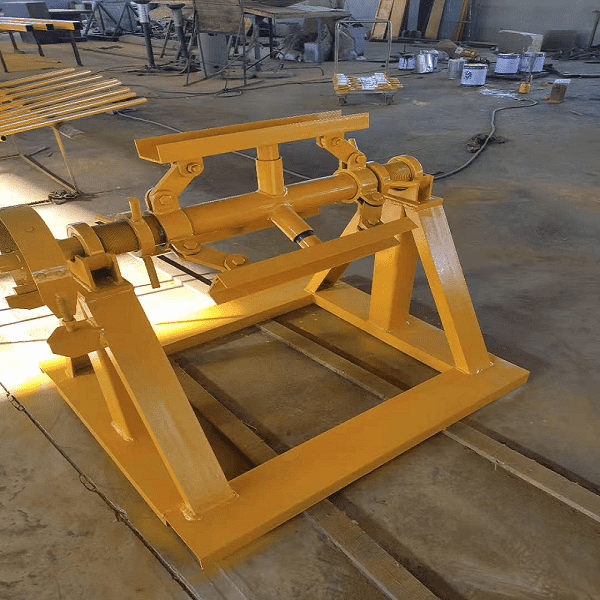

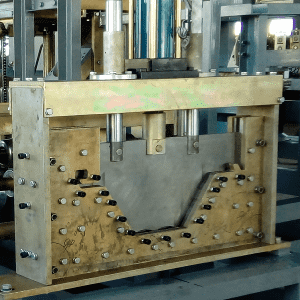

The machine include :manual decoiler—punching—-forming—cut—Curving

1. Features

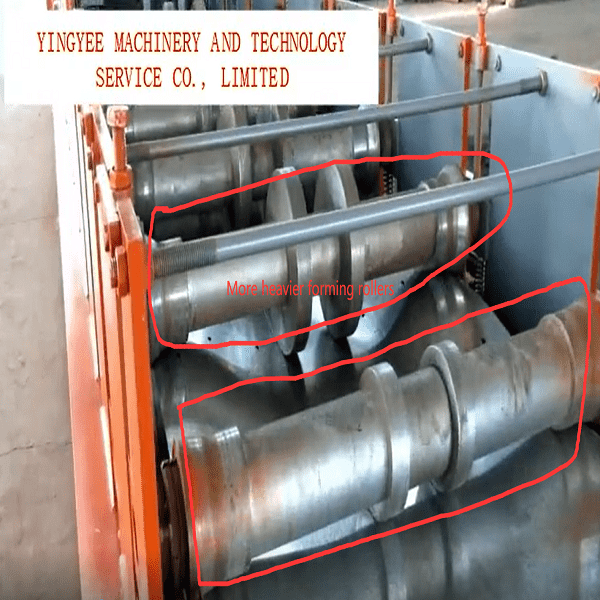

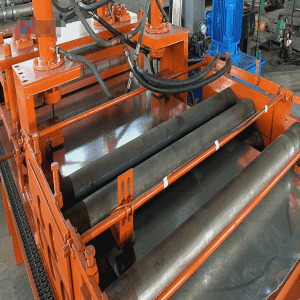

1.1 Rollers are made of good white steel processed with polishing.

1.2 We needn’t to adjust the gaps between rollers, and can feed 0.6-1.5mm color steel sheets.

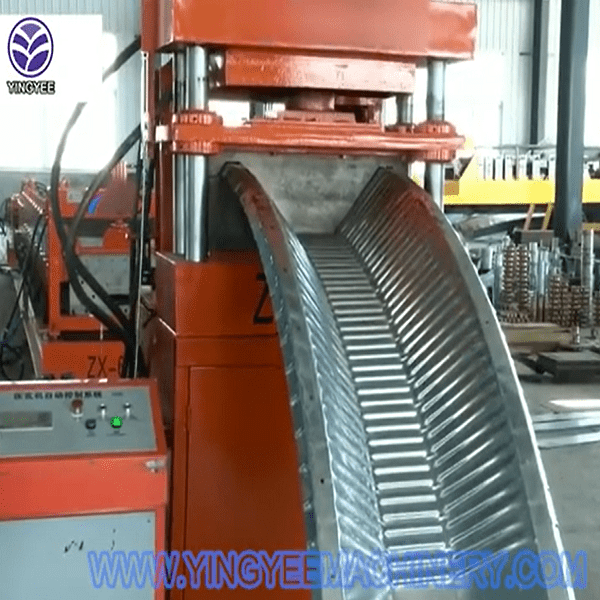

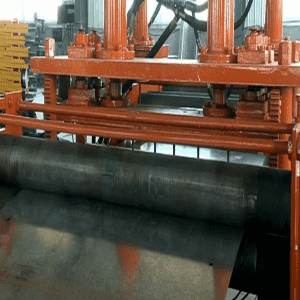

1.3 The finished colored will be very large span, high corrugation, high tension strength.

2. Main technical data of YY-680:

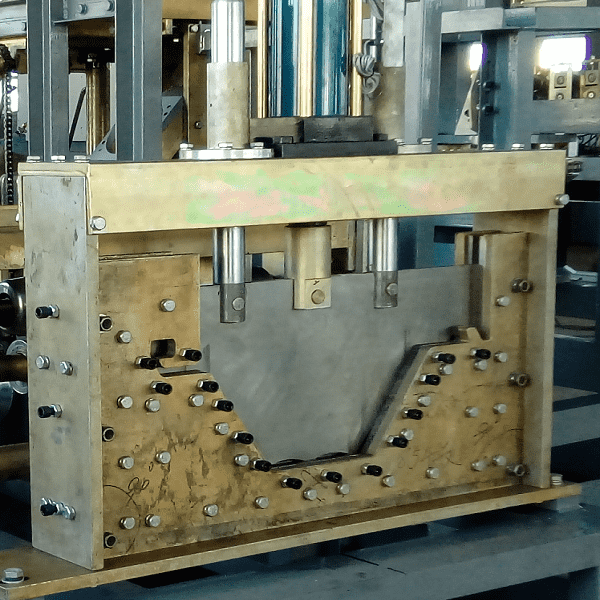

1. Punching part Size: 2900mmx1400mmx1300mm

Straight panel part size:10000mmx1400mmx1600mm

Bending panel part size:1600mmx1300mmx2500mm

Oil pump part size: 1200mmx1200mmx1400mm

2. Total weight: About 15000KG

3. Controlling System: PLC (Siemens)

4. Punch motor Power: 4kw

5. Forming Power: 7.5kw

6. Bending Power: 7.5kw

7. Cutting Power: 3.0kw

8. Oil pump motor power:7.5kw

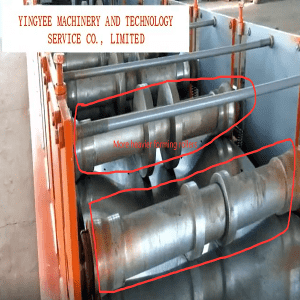

9. Material of rollers: 45#steel, quenched HRC 58-62

10. Material of roller shafts: 45#steel 75mm shafts diameter

11. Material of cutting blade: Cr12Mov steel

12. Step of rollers: 16 steps

13. Feeding Width: 1000mm.

14. Effective Width: 680mm as drawing

15. Thickness of the coil: 0.6-1.6mm

16. The depth of the groove: according drawings

17. max span:42 m

18.Operating factor of the panel: 64%