2018 High quality Roof Tile Machine - W beam guardrail roll forming machine – Yingyee

Short Description:

2018 High quality Roof Tile Machine - W beam guardrail roll forming machine – Yingyee Detail:

Basic Info

Model No.:YINGYEE013

Warranty:12 Months

Delivery Time:30 Days

After Service:Engineers Available To Service Machinery Overseas

Type:Steel Frame & Purlin Machine

Material:GI, PPGI, Aluminum Coils

Cutting Mode:Hydraulic

Voltage:380V/3Phase/50Hz Or At Your Request

Material Of Cutting Blade:Cr12

Forming Speed:5-10m/min(excluding Punching)

Way Of Driven:Gear Box

Additional Info

Packaging:NUDE, wooden case, plastic film

Productivity:200 sets/year

Brand:YY

Transportation:Ocean,Land,Air

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

HS Code:84552210

Port:Tianjin,Qingdao,Xiamen

Product Description

W beam guardrail forming machine W beam Guardrail Roll Forming Machine is our hot sale highway guardrail roll forming machine, W beam guardrail roll forming machine includes decoiler, punching, roll forming machine, output table. If you need the highway guardrail roll forming machine, please send me your sample drawing of guardrail, we will design the W beam guardrail roll forming machine for you.

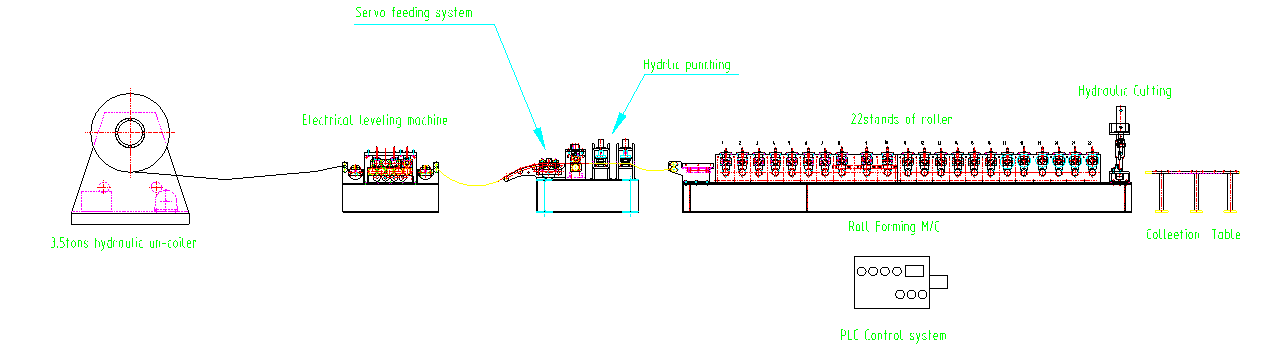

Working Flow: Decoiler – Leveling machine – Servo feeding system – Hydraulic punching – Feeding guide – Main Roll Forming Machine – PLC Contol System – Hydraulic Cutting – Output Table

Technical parameters:

| Matching material | Galvanized, PPGI, Aluminum |

| Material thickness range | 2-4mm |

| Main motor power | 18.5KW |

| Hydraulic motor power | 15KW |

| Forming speed | 8-10m/min(include punching) |

| Rollers | about 18 rows |

| Material of rollers | Cr12 |

| Shaft material and diameter | 106mm, material is 40Cr |

| Way of driven | Chain transmission or Gear box |

| Material of cutter blade | Cr 12 mould steel with quenched treatment 58-62℃ |

| Controlling system | Siemens PLC |

| Voltage | 380V/3Phase/50Hz |

| Total weight | about 8 tons |

| Size of the machine | L*W*H 12m*1.5m*1.2m |

Pictures of machine:

Company information:

YINGYEE MACHINERY AND TECHNOLOGY SERVICE CO.,LTD

YINGYEE is the manufacturer specialized in various cold forming machineries and automatic production lines. We have a wonderful team with highly technology and excellent sales, which offer professional products and related service. We paid attention to quantity and after service, got great feedback and honor formal the clients. We have a great team for after service. We have sent several patch after service team to oversea to finish the products installation and adjustment. Our products were sold to more than 20 countries already. Also included US and Germany. Main product :

- Roof roll forming machine

- Roller Shutter Door Roll Forming Machine

- C and Z purlin roll forming machine

- Downpipe Roll Forming Machine

- Light Keel Roll Forming Machine

- Shearing Machine

- Hydraulic decoiler

- Bending machine

- Slitting machine

FAQ:

Training and Installation :

1. We offer installation service local in paid, reasonable charge.

2. QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service:

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period

2. Effective communication

3. Interface customized.

Looking for ideal W Beam Guardrail Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the W Beam Guardrail Forming Machine are quality guaranteed. We are China Origin Factory of Guardrail Forming Machine. If you have any question, please feel free to contact us.

Product Categories : Guardrail (Highway) Roll Forming Machine

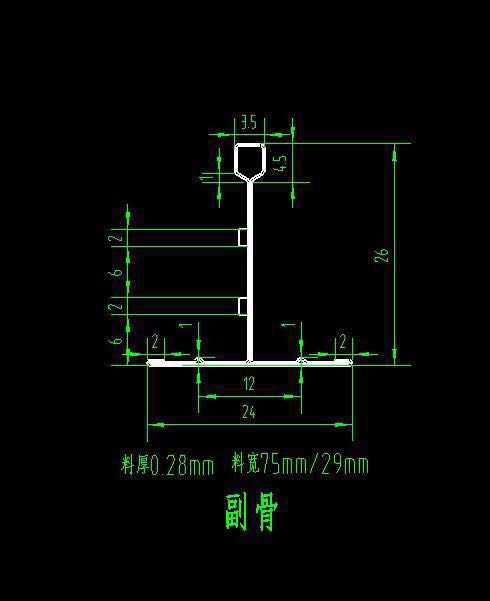

Product detail pictures:

Related Product Guide:

We now have a skilled, performance team to supply good quality services for our consumer. We often follow the tenet of customer-oriented, details-focused for 2018 High quality Roof Tile Machine - W beam guardrail roll forming machine – Yingyee, The product will supply to all over the world, such as: Karachi, Mexico, Turkmenistan, Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products to customers at low cots, we are committed to improving its capacities in research, development, manufacturing and management. We have honored to receive recognition from our customers. Till now we have passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of "quality of survival, the credibility of development" for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.