100% Original Express Way Guard Rail Roll Forming Machine - Stone Coated Roof Making Machine – Yingyee

Short Description:

100% Original Express Way Guard Rail Roll Forming Machine - Stone Coated Roof Making Machine – Yingyee Detail:

Basic Info

Control System:PLC

Delivery Time:30 Days

Warranty:12 Months

Speed:5-6 Pieces

Cutting Mode:Hydraulic Cutting

Products:Roof Sheet Roll Forming Machine

Type:Roof

Voltage:As Customer’s Requirement

Material:Pre-printed Coil,galvanized Coil,Aluminum Co

Additional Info

Packaging:NUDE

Productivity:200 sets/year

Brand:YY

Transportation:Ocean

Place of Origin:Hebei

Supply Ability:200 sets/year

Certificate:CE/ISO9001

HS Code:84552210

Port:Tianjin Xingang

Product Description

Stone Coated Roof Making Machine colorful coated metal roof tile is a new advanced roof material which adopt the high and new technology,use the non-corrosibility al-zin steel as the basic plate,use the acrylic resin which has the good weather resistance as the adhesives,use the colorful natural sandy gravel as the surface.

Technical parameters:

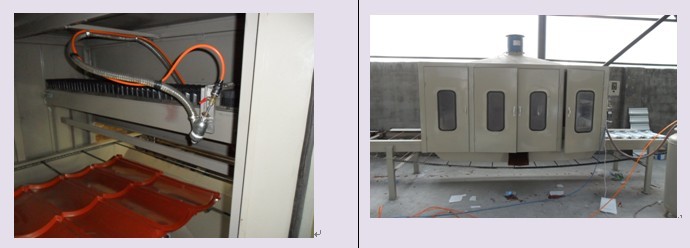

1. Auto bottom gule spraying section l Appearance size:4000*1000*2000 mm l Driving section:3KW Excitation motor or frequency speed regulation (as requirements ) l Automatic pressure spray tank:1set capability:200kg Range:0.6~1Mpa l Automatic glue machine motor: Servo motor, Power:750w, plc l Automatic spray gun:4 set(spare parts) l Dust collecting fan: 1set power:200w l Damp proof lamp:1pc power:100w l Conveying device:Chain reciprocating l Air compressor:1set power:7.5kw l Dust control of axial flow fan:1set power: 200w

l Agitator: 1set power:1.5kw

Equipment production environment configuration: 1 equipment linear arrangement : the length of the workshop is not less than 80 meters, the width of not less than 15 meters,

2 equipment turning arrangement : length of the workshop is not less than 40 meters, the width of not less than 15 meters.

2. Auto stone coated section l Appearance size:3500×1000×1500mm l Framework: Steel welding l Conveying device:Chain reciprocating l Automatic sand hopper: 1set capability:200kg l Bucket lift:1 set l Manual sandblast gun:4sets

3. The first time drying section l Appearance size:25000×1000×1200 mm l Framework: Steel welding l Frame type thermal insulation wall: 1.2mm cold steel with Rock wool l Automatic temperature controller:4set Range:0°~160° l Infrared heating tube: 30pcs Power:30kw l Conveying device:Chain reciprocating l Air cooling device:1 set Power:200w 4. Auto face glue spraying section l Appearance size:3000×1000×2000 mm l Framework: Steel welding l Damp proof lamp:1pc Power:100w l Automatic pressure spray tank:1set capability:200kg Range:0.6~1Mpa l Conveying device:Chain reciprocating l Automatic spray gun:4 set(spare parts) l Manual patch glue gun:4 set l Dust control of axial flow fan:1set power: 200w l Automatic glue machine motor: Servo motor, Power:750w 5. The second time drying section l Appearance size:30000×1000×1200 mm l Framework: Steel welding l Frame type thermal insulation wall: 1.2mm cold steel with Rock wool

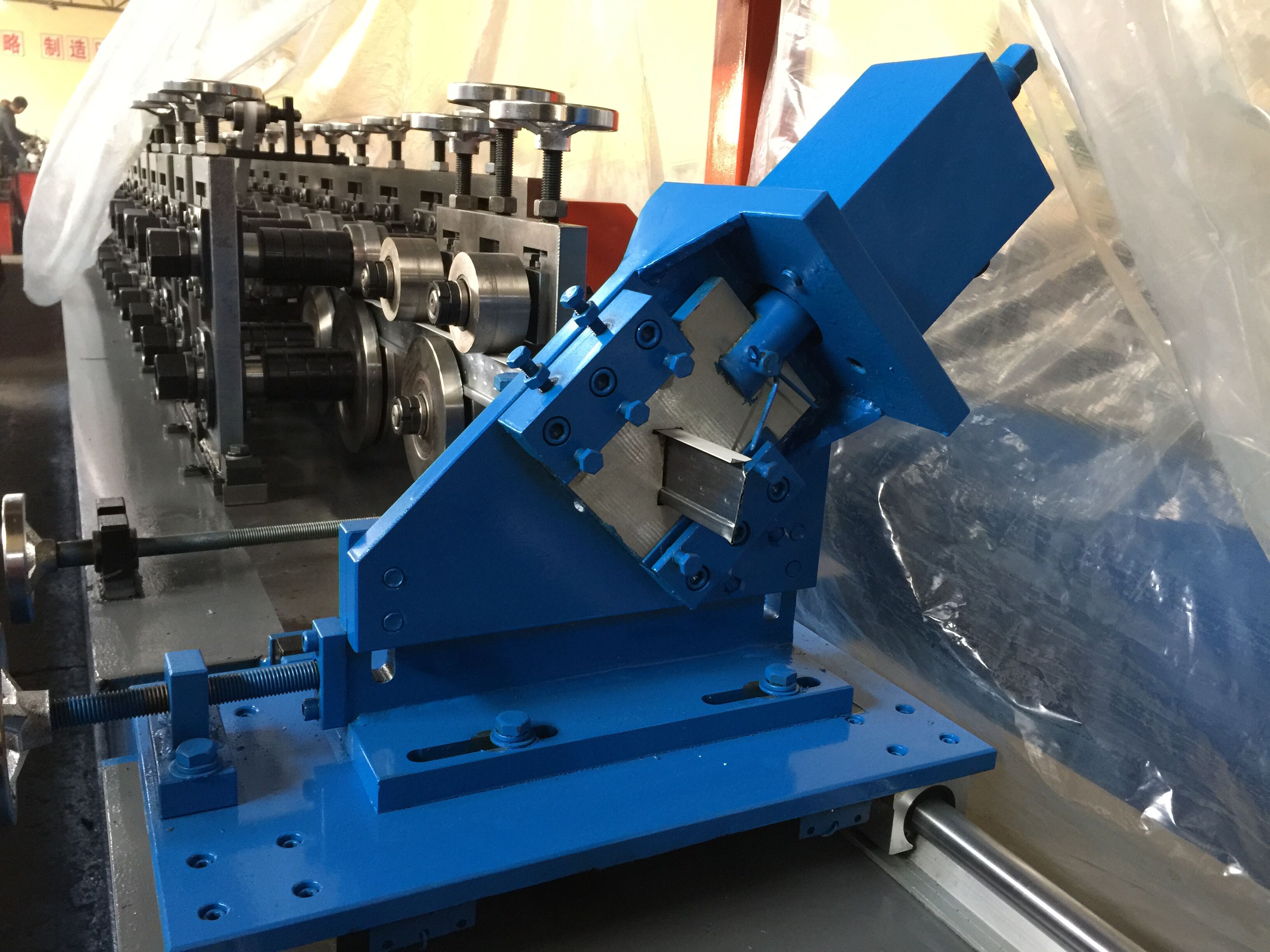

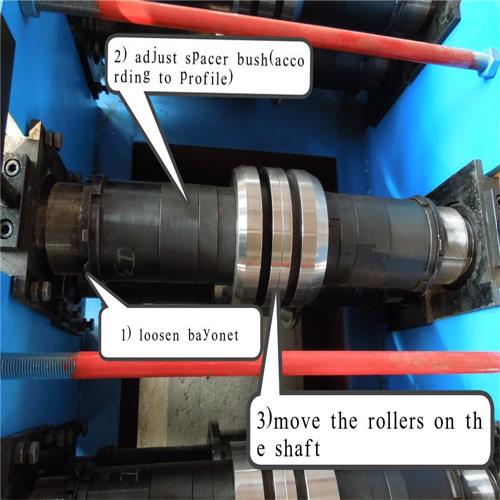

Pictures of machine:

Product detail pictures:

Related Product Guide:

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for 100% Original Express Way Guard Rail Roll Forming Machine - Stone Coated Roof Making Machine – Yingyee, The product will supply to all over the world, such as: Argentina, Congo, Monaco, Many years of work experience, we have now realized the importance of providing good quality products and solutions and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.